Drying of

Sewage Sludge

The concept of

GEROLDINGER's vertical shaft dryer is simple:

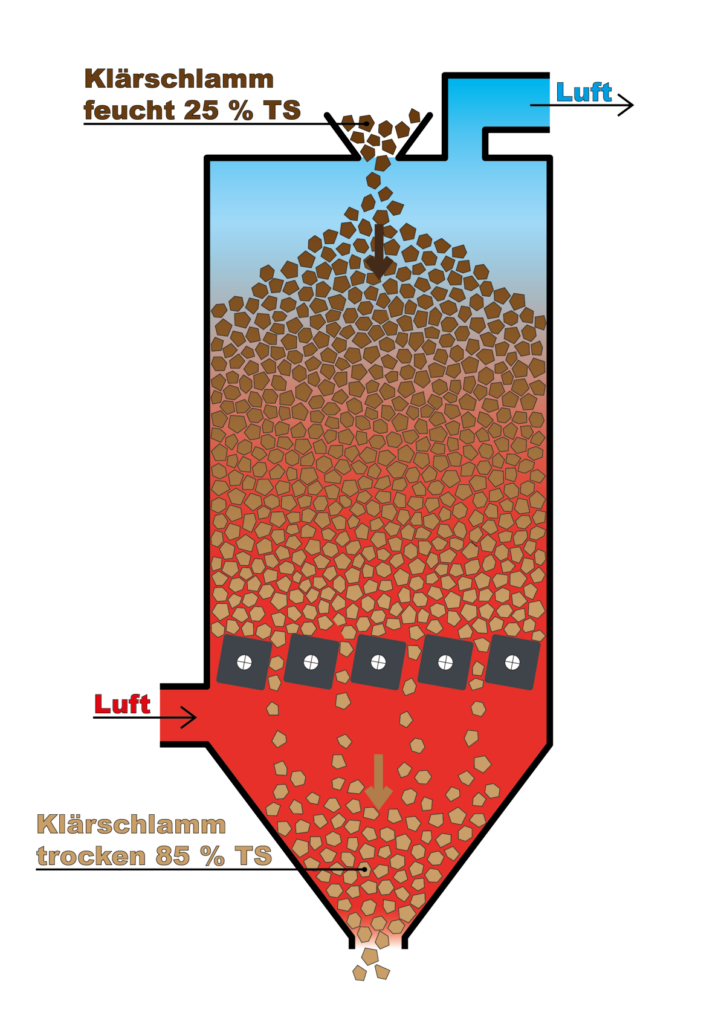

The essential drying unit consists of a sludge feed with dosing function, the gas-flowable tank, a controllable tilting bar bottom (controlling the air flow and discharging the dry material) and a powerful ventilation system. Hot air flows through the moist sludge through narrow openings in the floor, absorbing water in the process. Warm air flows through the moist sludge through narrow openings in the floor, absorbing water in the process. Our system uses the convective drying method.

Dried material is continuously discharged during the drying process – there is no need to pause the airflow. The volume in the chamber always remains unchanged because the removed dry material is equalized again by refilling moist sludge.

With our method, the water content of sewage sludge can be reduced to as little as 2%, which corresponds to 98% dry matter.

Advantages:

- Drastic savings in disposal costs due to mass reduction

- Reduction of storage area for drained sludge

- Flexibility in costs of disposal by setting various degrees of dryness

- Tapping of new sources of income through contract drying

- Recycling of waste heat that was previously hardly used

- Precautionary measure for unforeseeable changes in legal requirements