Startseite » Components » Conveying

Conveying

You want to smoothly move your product from A to B?

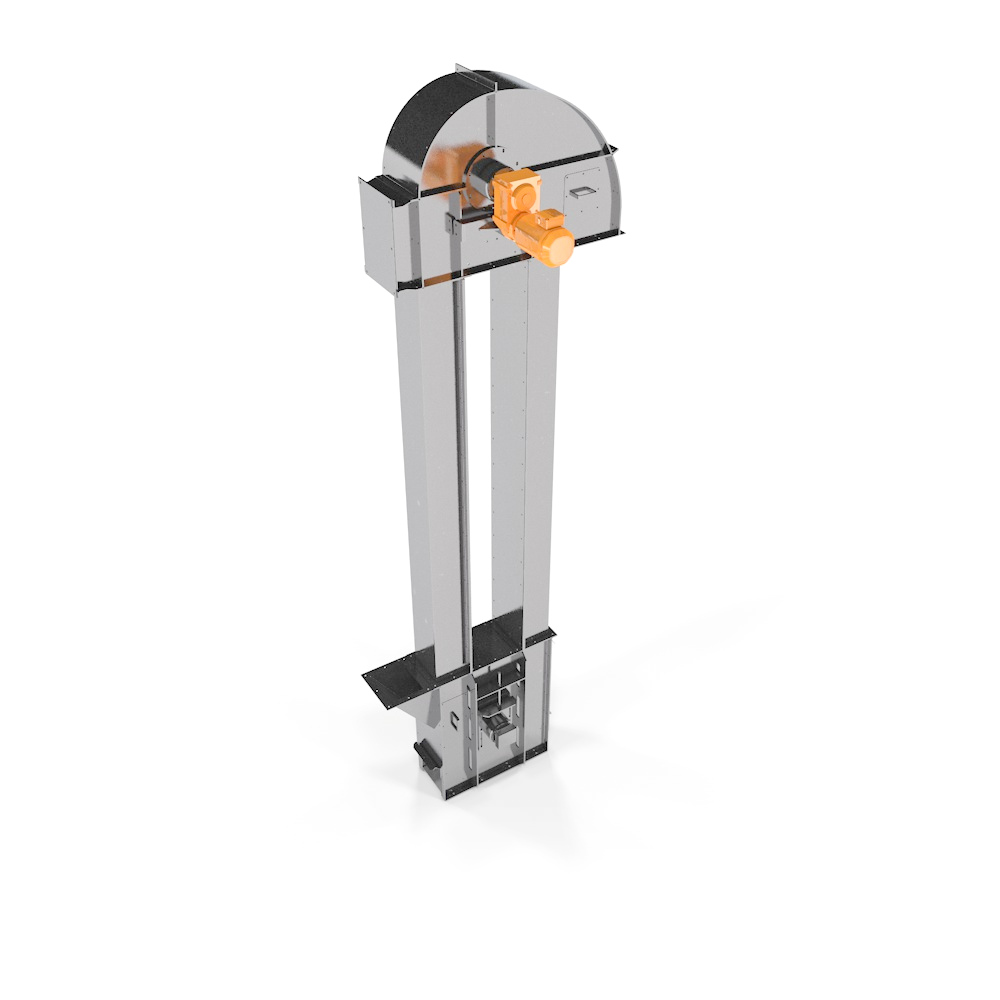

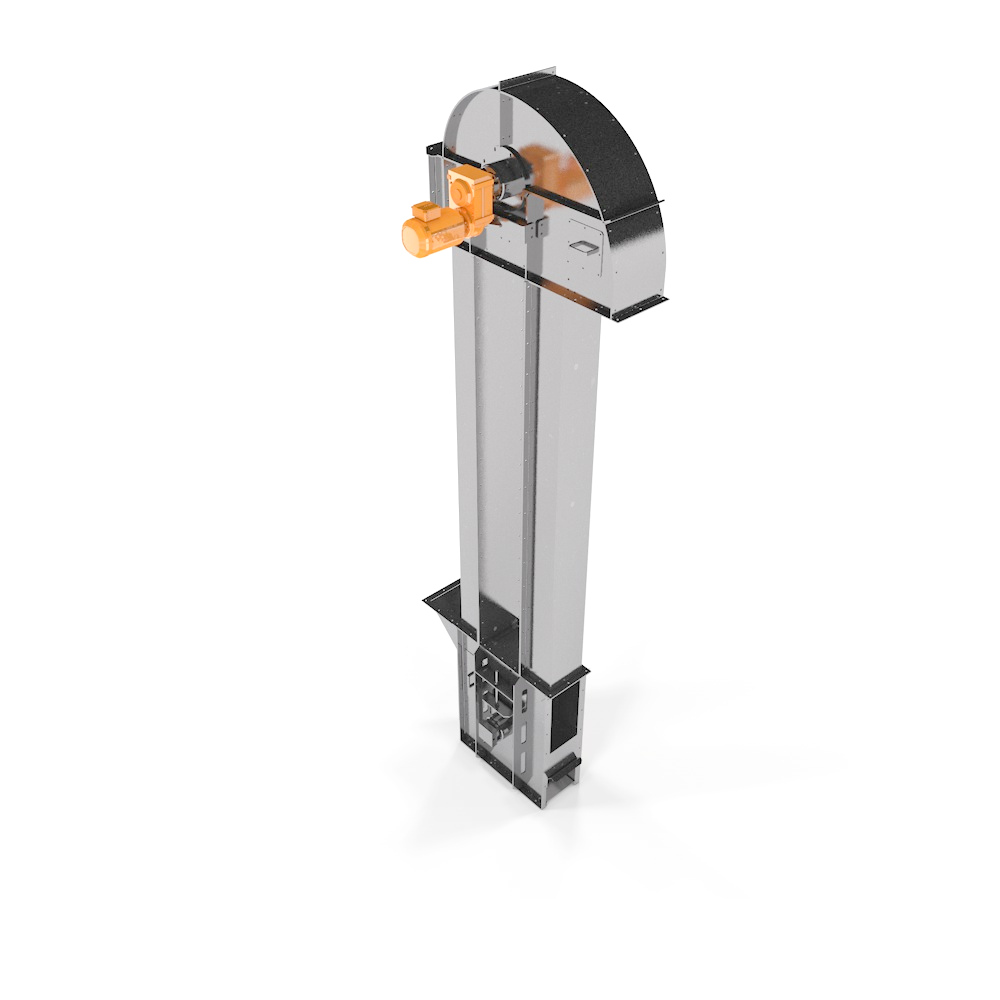

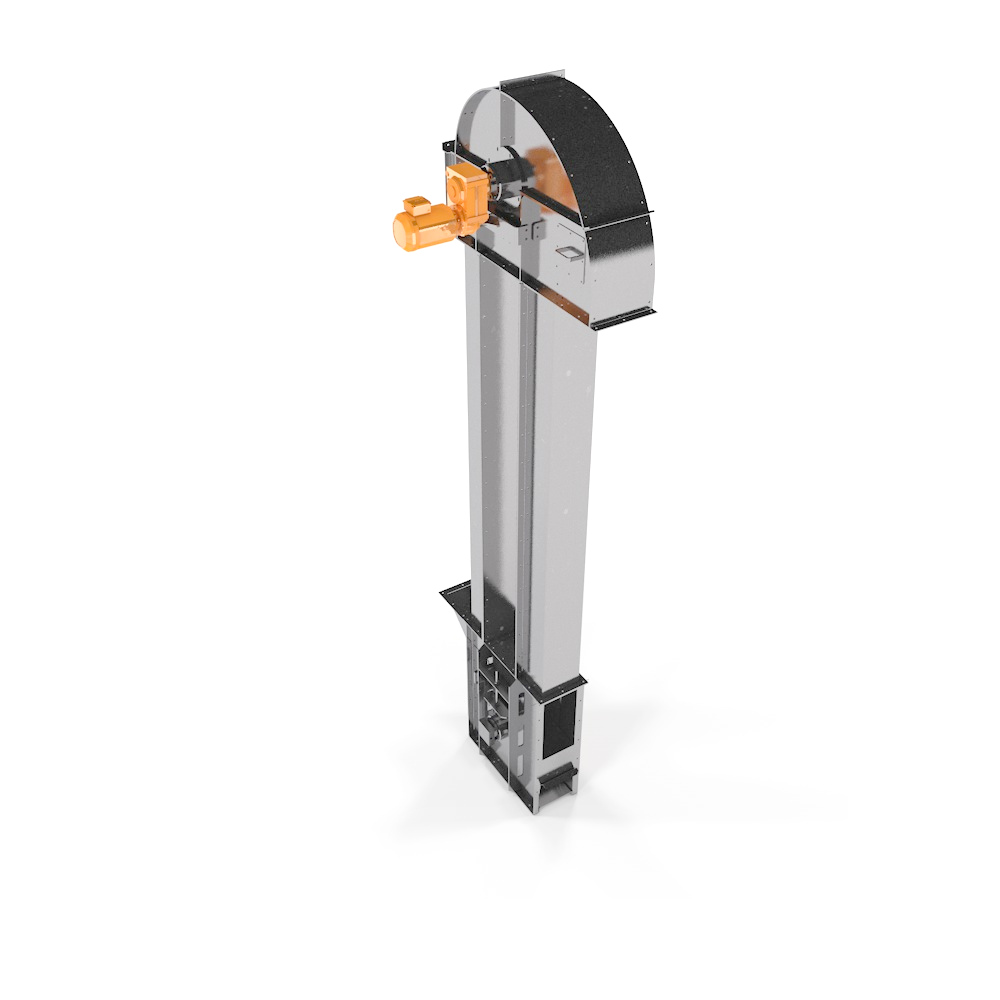

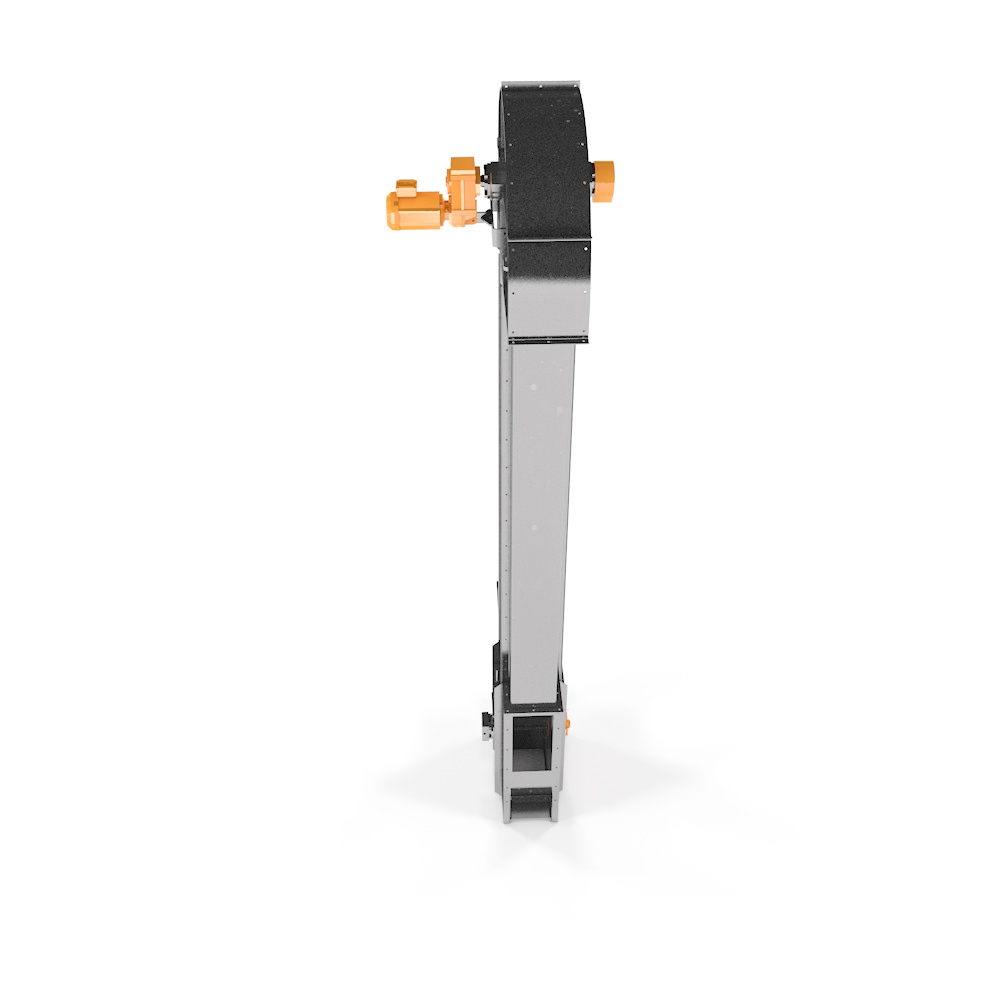

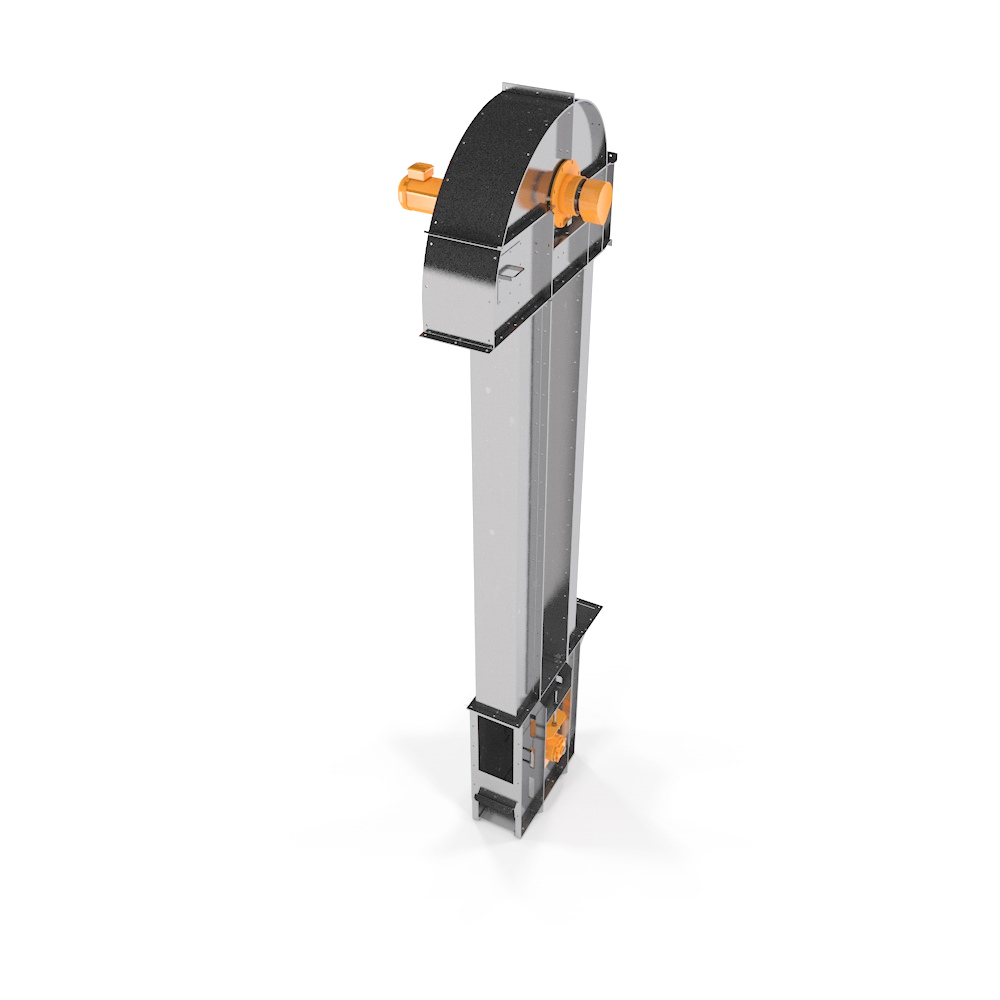

BUCKET ELEVATOR

Applications:

– All bulk materials

Advantages:

– Closed system

– Inexpensive solution for vertical bulk material transport

Technical Details:

– Belt pulley diameter: 360 – 1,250 mm

– Bucket width: 140 – 800 mm

– Height: 3,0 – 50,0 m

– Conveying capacity: 1 – 400 m³/h

Other Configurations:

– Suitable for indoor dust explosion zone 20 and outdoor dust explosion zone 22

Materials:

– Normal steel S235 painted (<< 480 µm)

– Stainless steel 1.4301

– Stainless steel 1.4571

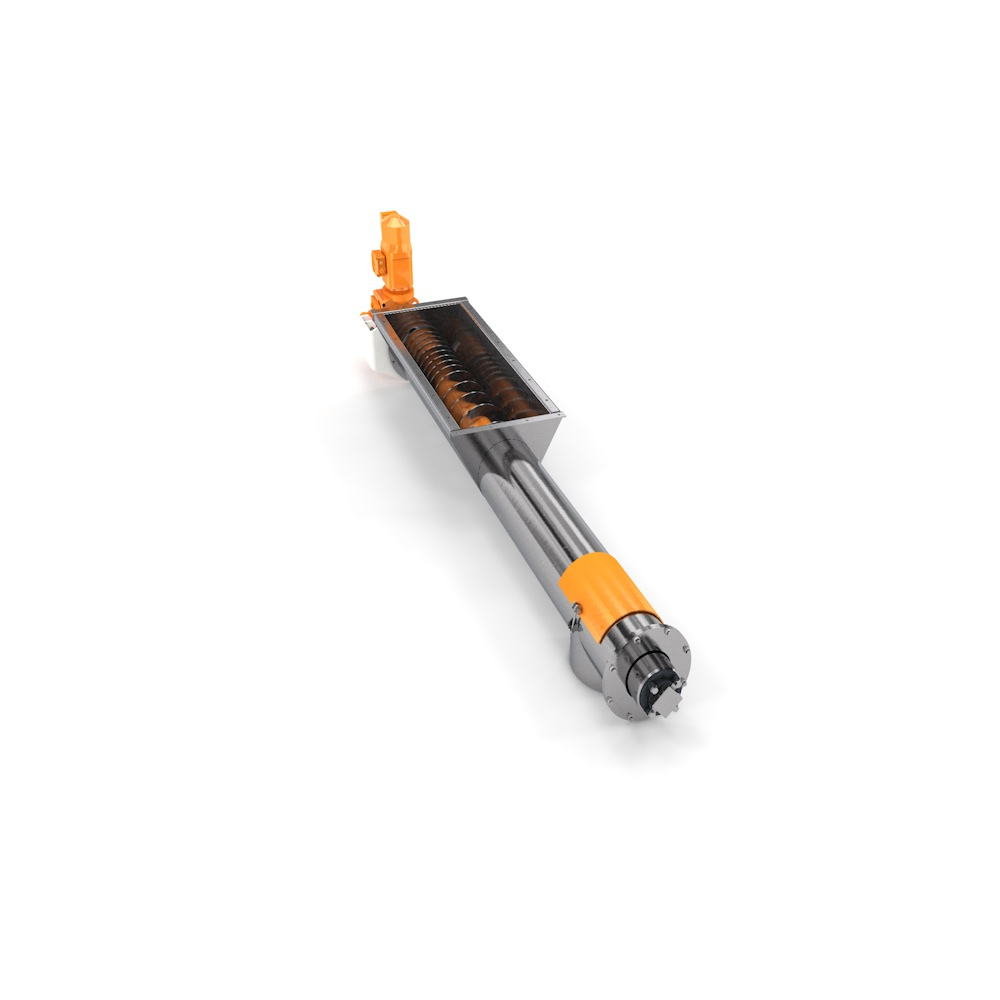

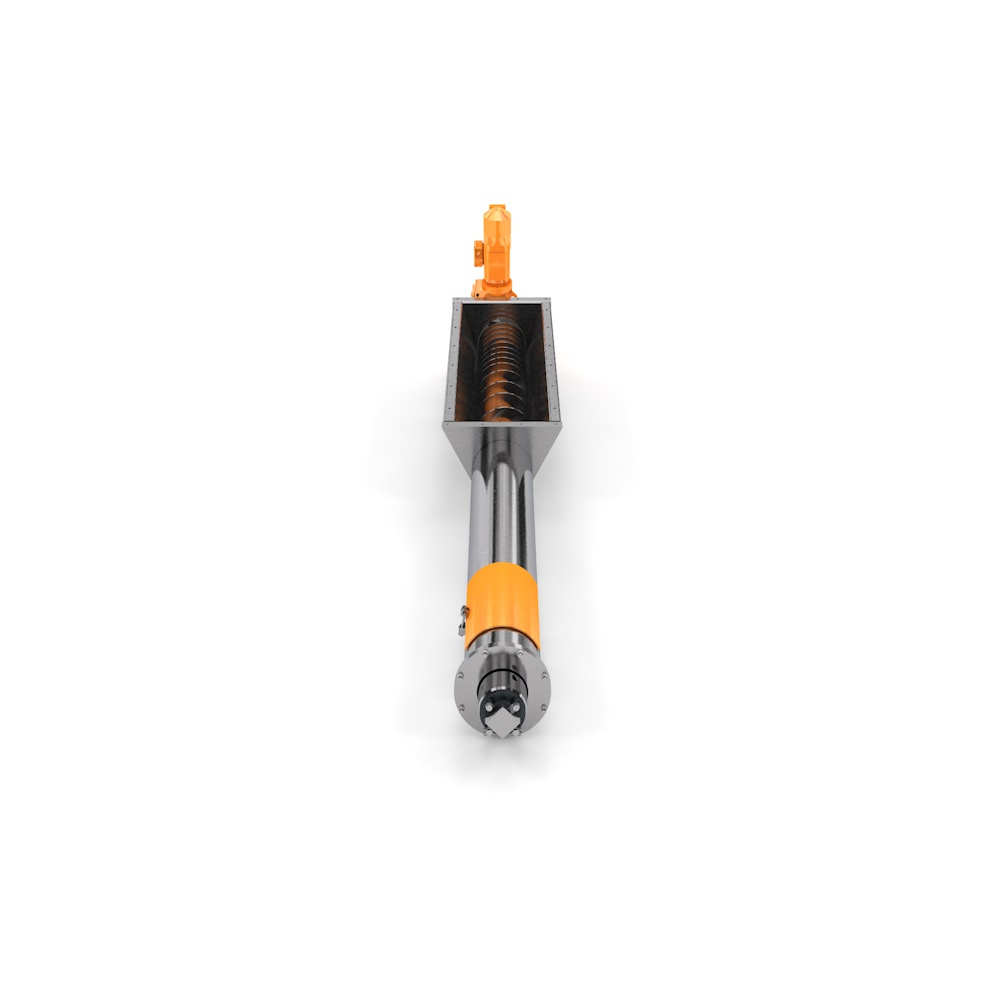

SCREW CONVEYER

Applications:

– All bulk goods except for pasty bulk goods (e.g. filter cake).

Advantages:

– Closed system

– Can also be reversed (transport to the left or right)

Technical Details:

– Diameter: 100 – 800 mm

– Length: 1,0 – 16,0 m

– Conveying capacity: 1 – 400 m³/h

– Inclinations: 0 – 60°

Other Configurations:

– Suitable for indoor dust explosion zone 20 and outdoor dust explosion zone 22

– Design as tubular or trough screw conveyor

Materials:

– Normal steel S235 painted(< 480 µm)

– Stainless steel 1.4301

– Stainless steel 1.4571

TROUGH CHAIN CONVEYOR

Applications:

– All bulk materials

Advantages:

– Closed system

– Multiple inlets and outlets possible

– Mechanical conveying over long distances possible

Technical Details:

– Width: 200 – 1.000 mm

– Length: 5,0 – 50,0 m

– Conveying capacity: 1 – 400 m³/h

– Inclination: 0 – 80°

Other Configurations:

– Version with one or two chains

– Suitable for indoor dust explosion zone 20 and outdoor dust explosion zone 22

Materials:

– Normal steel S235 painted (<< 480 µm)

– Stainless steel 1.4301

– Stainless steel 1.4571