Startseite » Components » Storing

Storing

Too little space for your bulk goods?

GEROLDINGER offers two different types of silos, both produced in Austria. Depending on the bulk material, required storage volume, available floor space and height, we tailor the optimal solution for you.

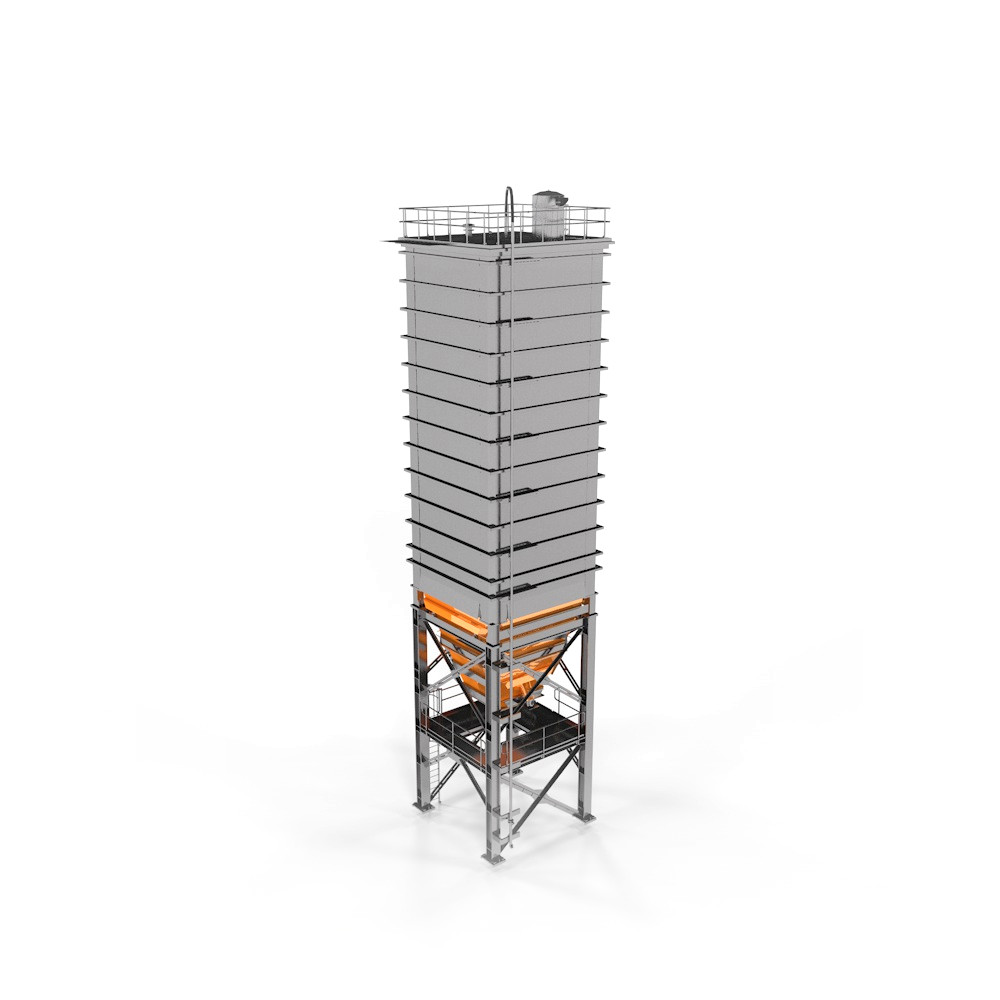

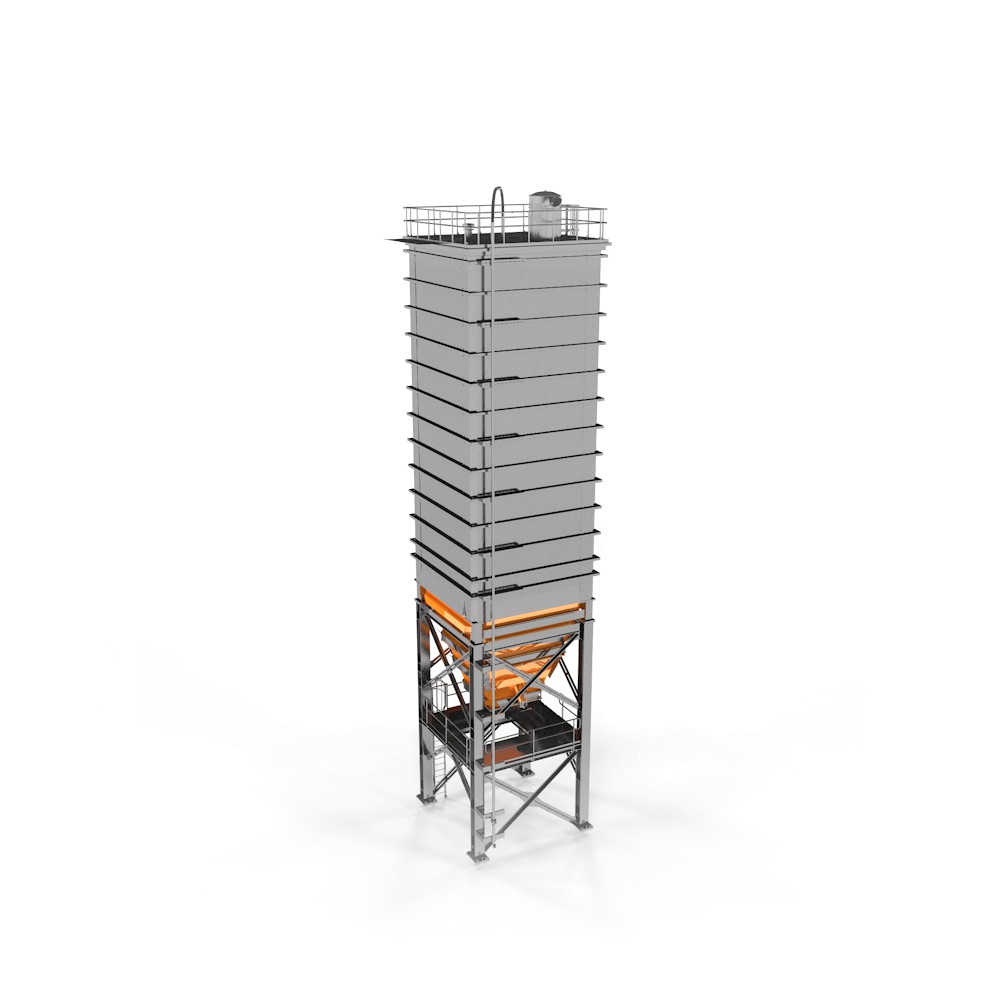

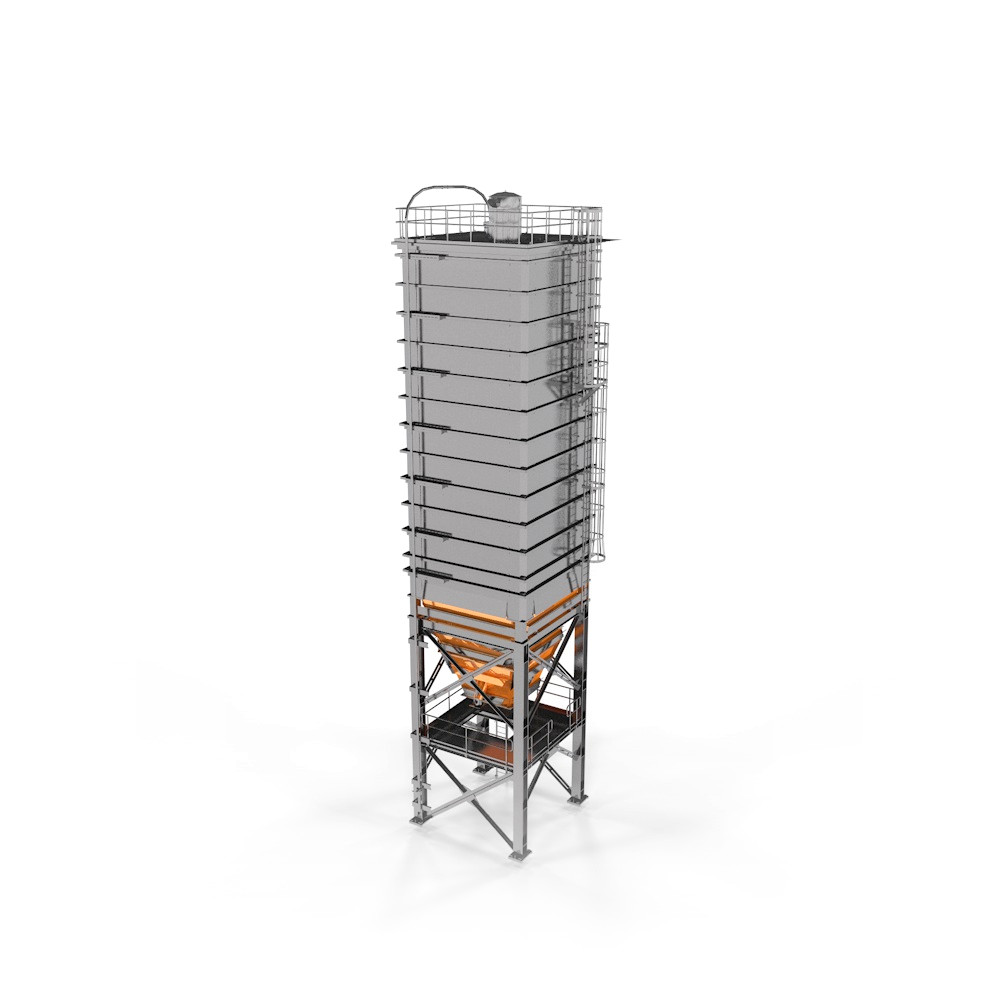

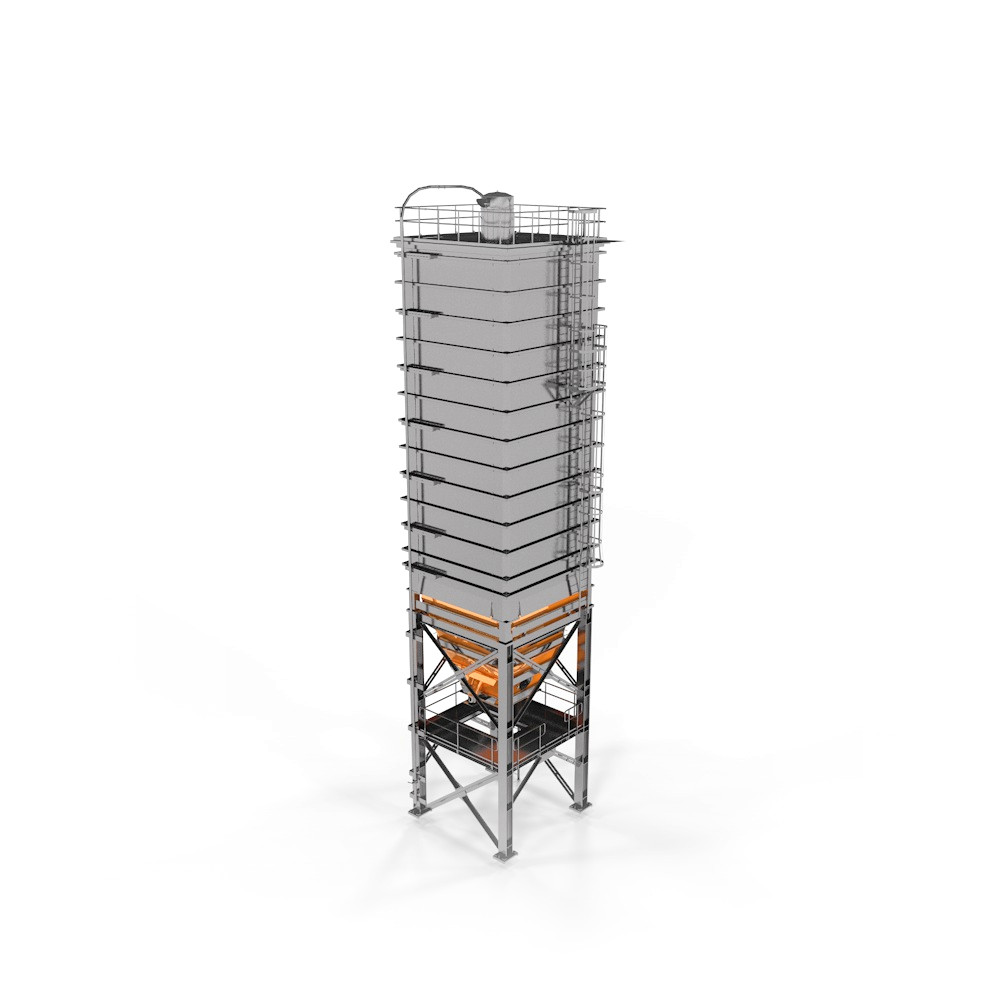

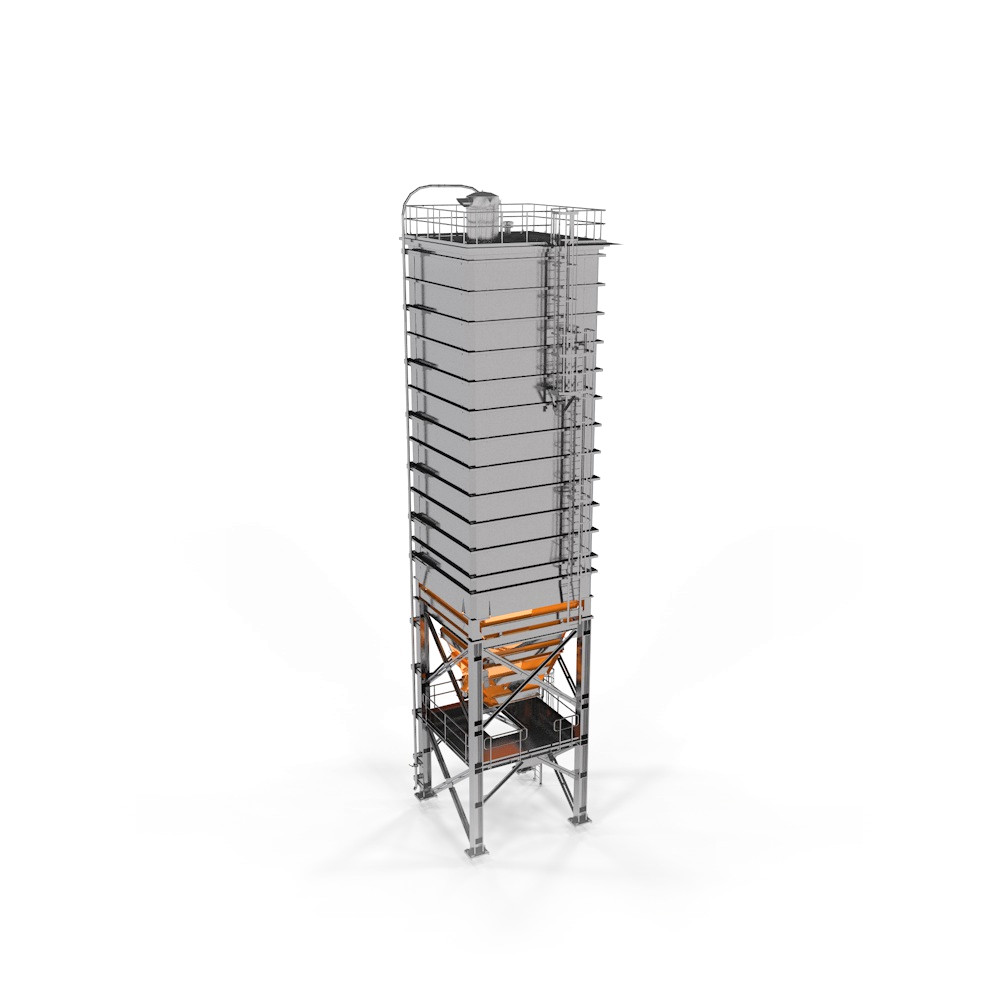

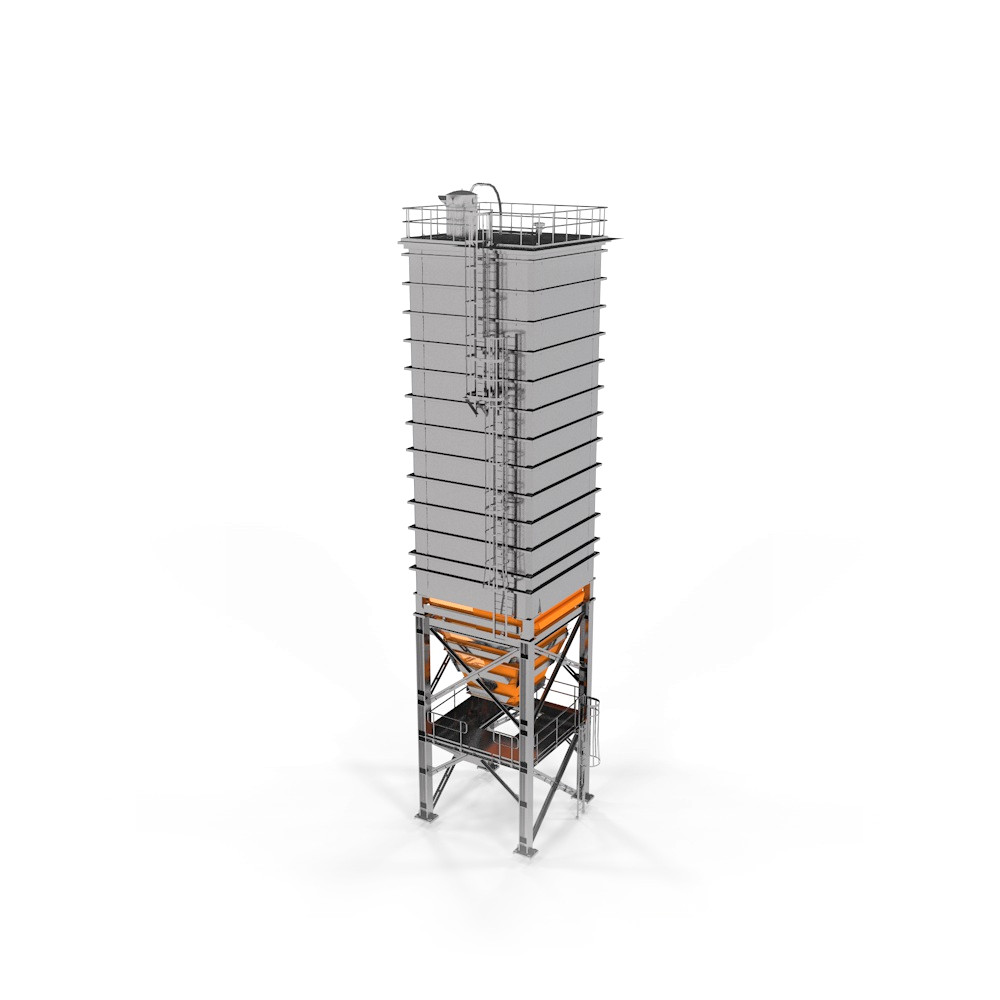

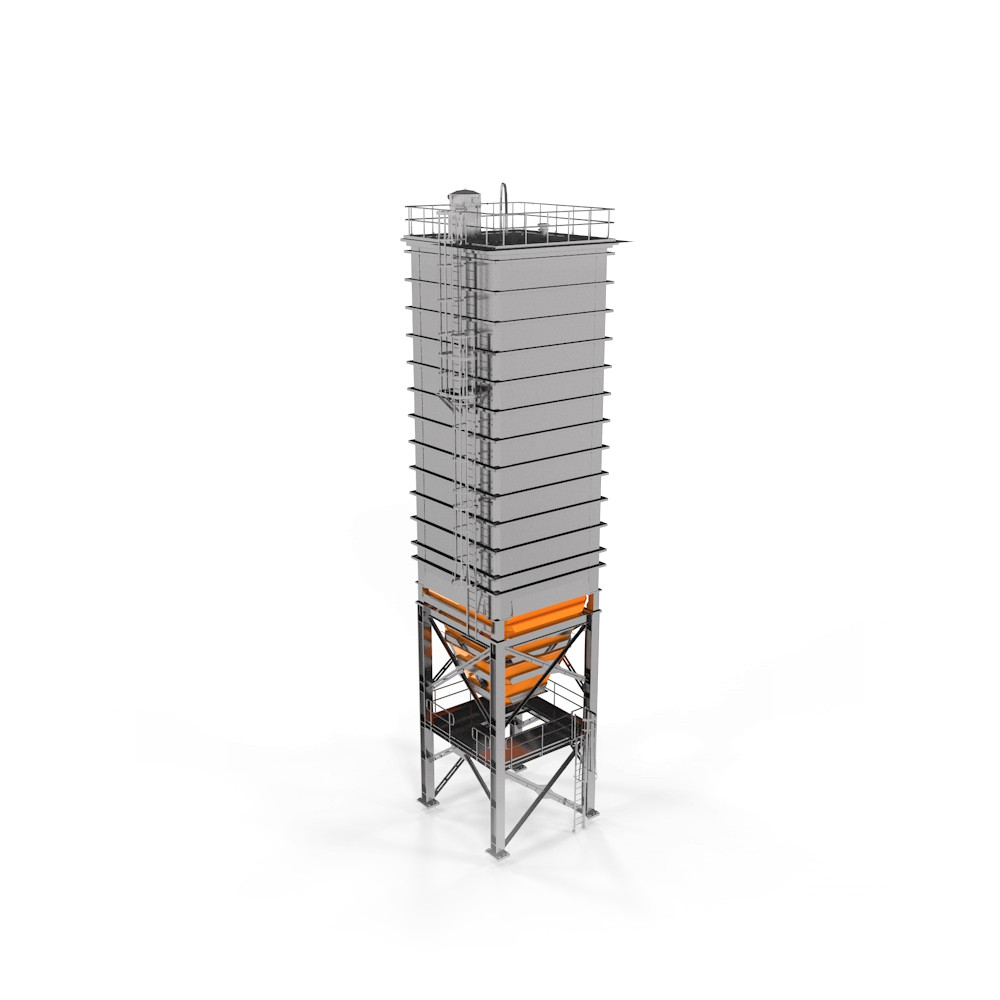

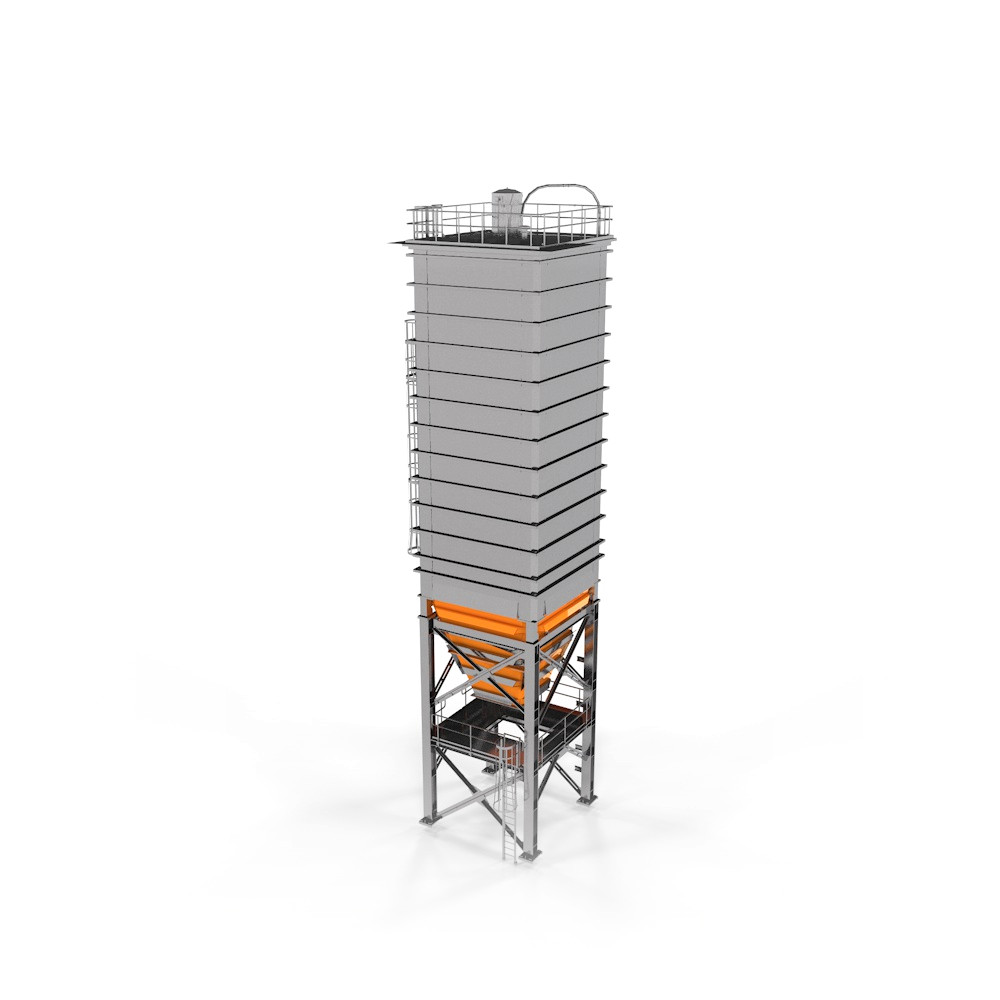

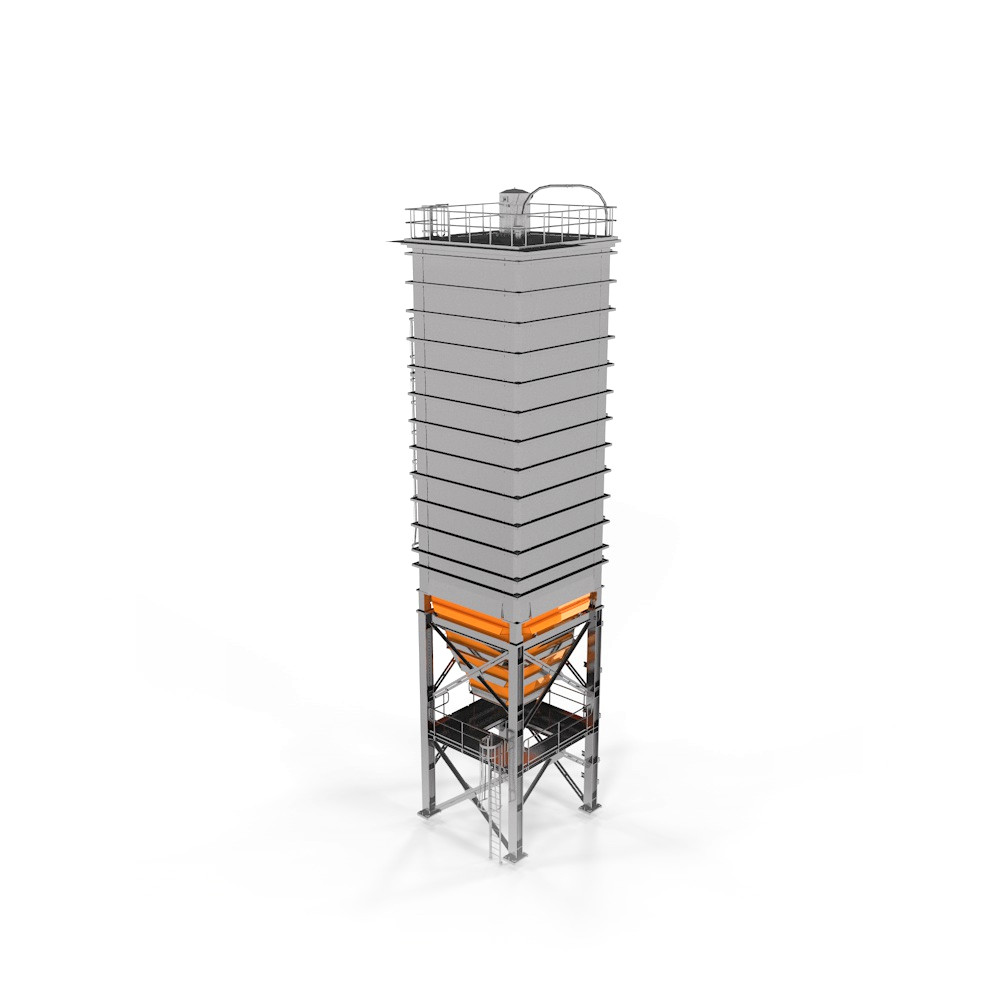

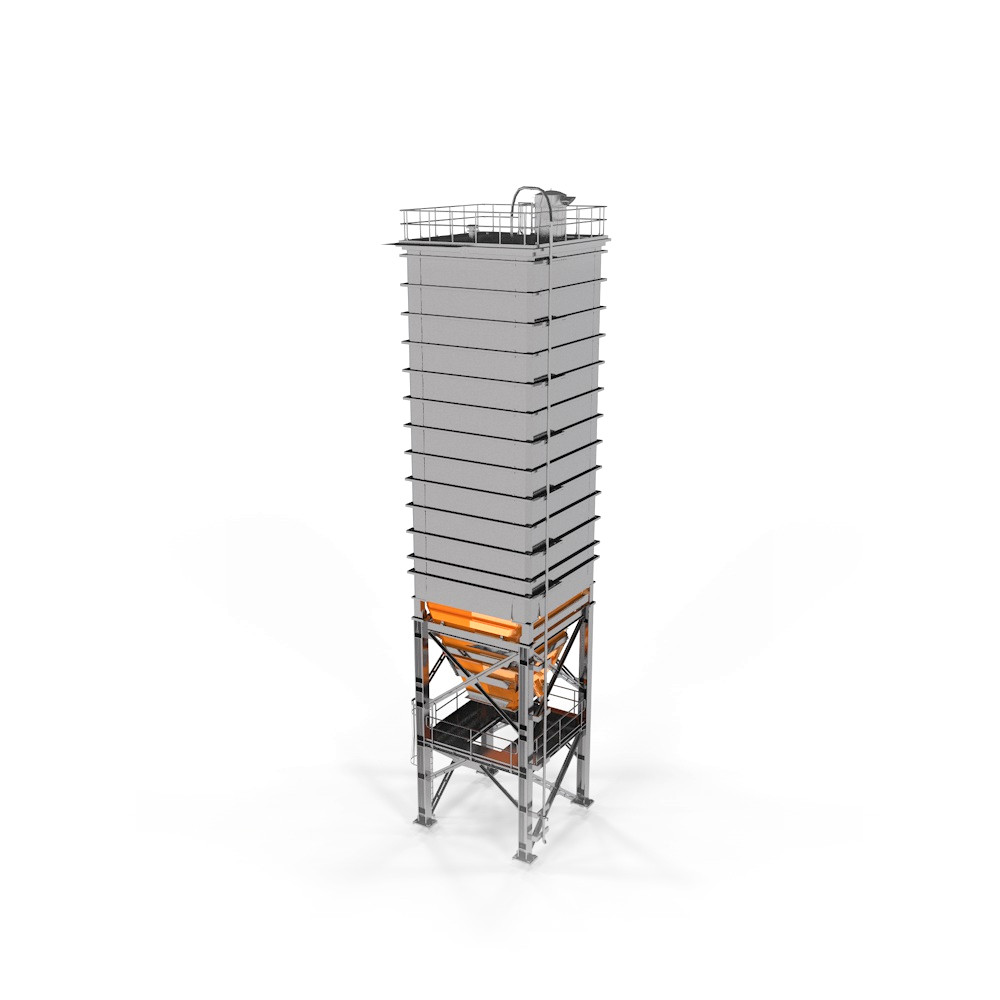

Multigon

Applications:

– All bulk materials

– Preferred for hygroscopic bulk solids (e.g. urea)

– Preferred for non-flowing bulk solids (e.g., film chips)

Advantages:

– Smooth walls on the inside

– Installation of several cells next to each other possible

– The available floor space can be used optimally

(angular design)

– Great insulation due to “sandwich” design

– Flexible walls (crusts blow off – hygroscopic bulk

materials)

– Low transport costs (transport in shipping containers is possible)

– No welding work on the construction site necessary

Technical Details:

– Axle dimension: 1,0 – 5,7 m

– Silo height: 4,8 – 49,8 m

– Storage volume: 5 – 1500 m³

– Pressure shock resistant up to 1,0 bar(ü)

– Roof inclination: 0°

– Discharge hopper inclination: < 80°

Other Configurations:

– Suitable for weighing

– Square or round outlet possible

– Suitable for dust explosion zone 20

Materials:

– Regular steel S235 painted (< 480 µm)

– Stainless steel 1.4301 or 1.4541

– Stainless steel 1.4571

Round Silo

Applications:

– Preferred for slightly cohesive bulk materials (e.g. flour)

– Preferred for hygroscopic bulk materials (e.g. urea)

Advantages:

– Small conveying capacities can be realized (fine dosing)

Technical Details:

– Inlet: 0,3 x 0,3 m

– Discharge capacity: 5 – 1.000 Kg

Other Configurations:

– Mostly in combination with weighing

– Suitable for inside dust explosion zone 20 and outside dust explosion zone 22

Materials:

– Normal steel S235 painted (< 480 µm)

– Stainless steel 1.4301

– Stainless steel 1.4571