Startseite » Components » Discharging

Discharging

Experiencing silo blockages?

GEROLDINGER offers the right discharge solution for every material. For this purpose, we primarily rely on rich experience. If necessary, the bulk material is examined in our lab to determine its physical properties.

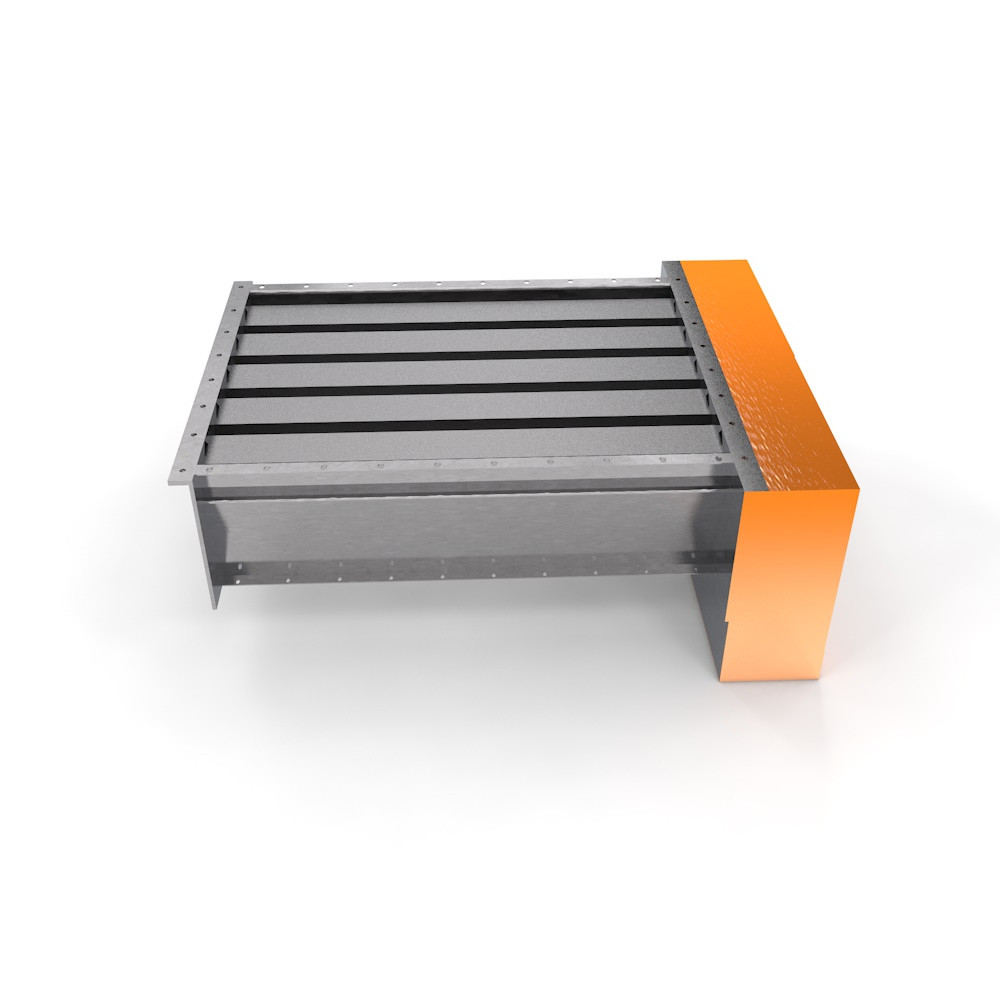

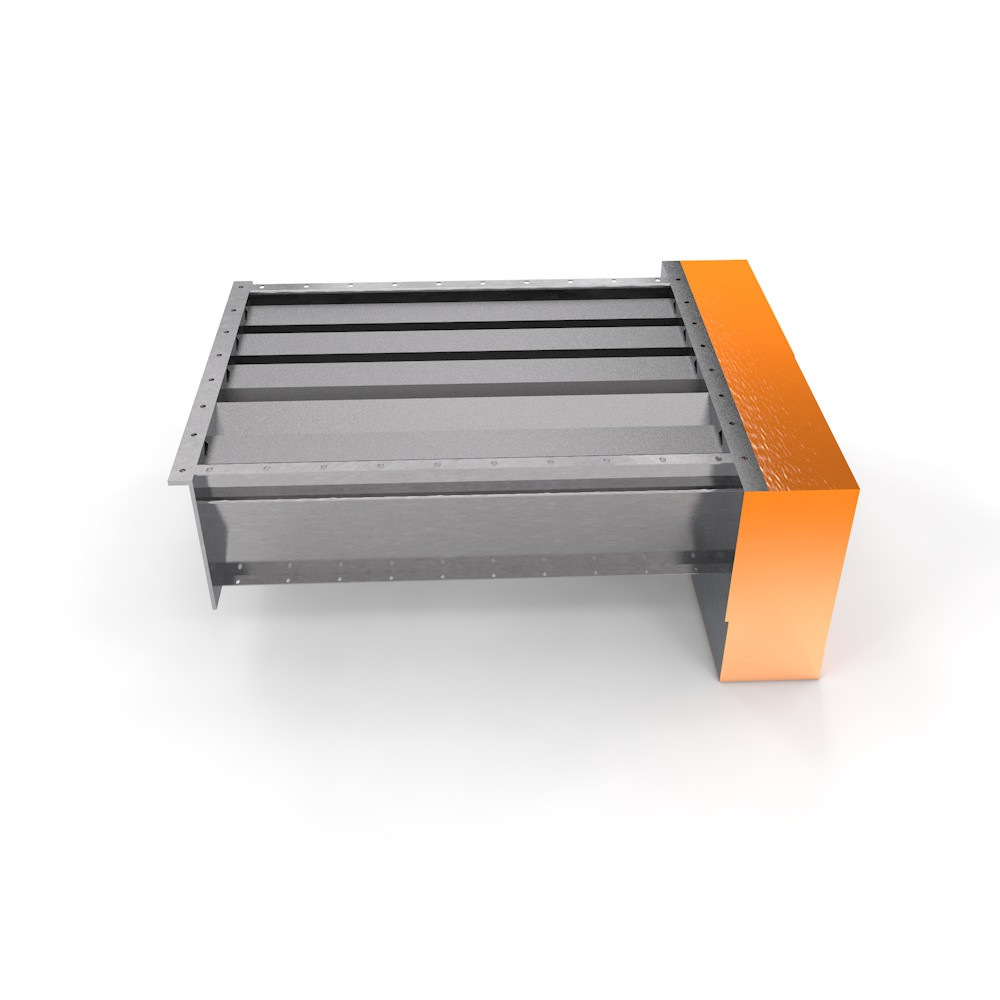

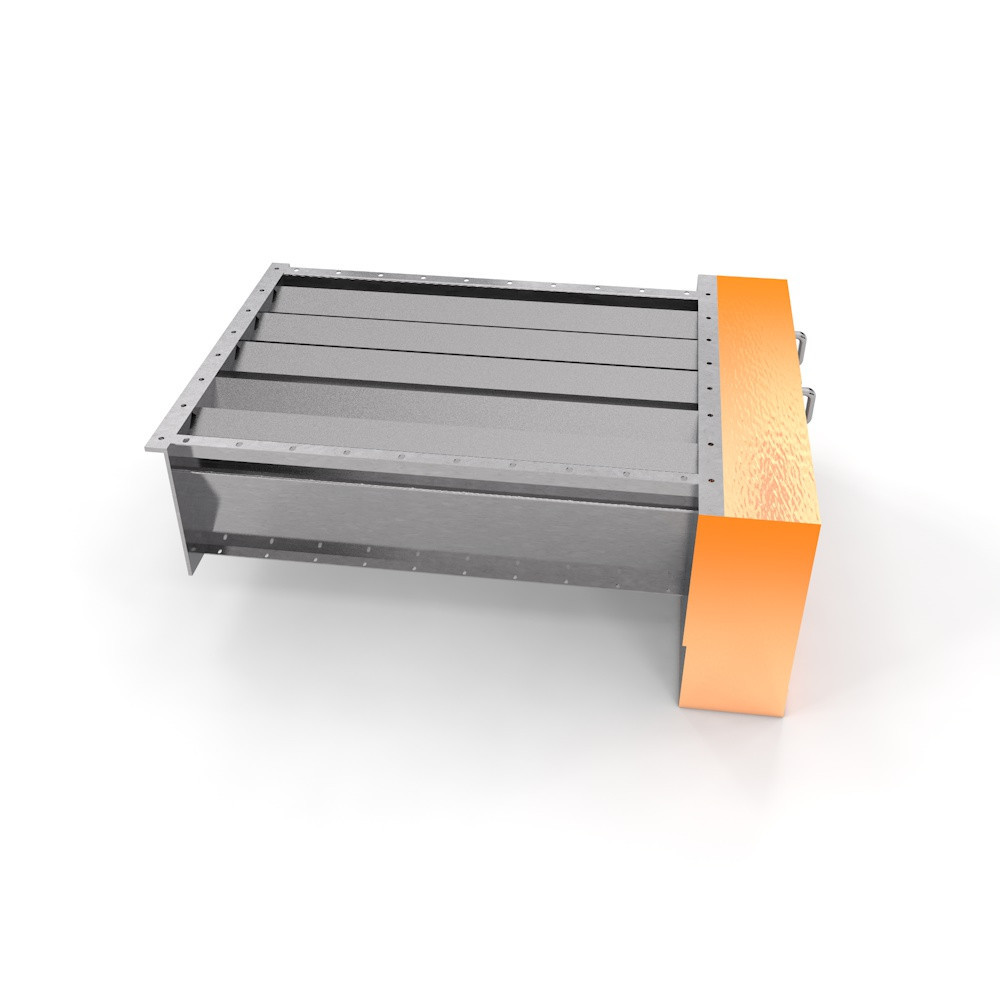

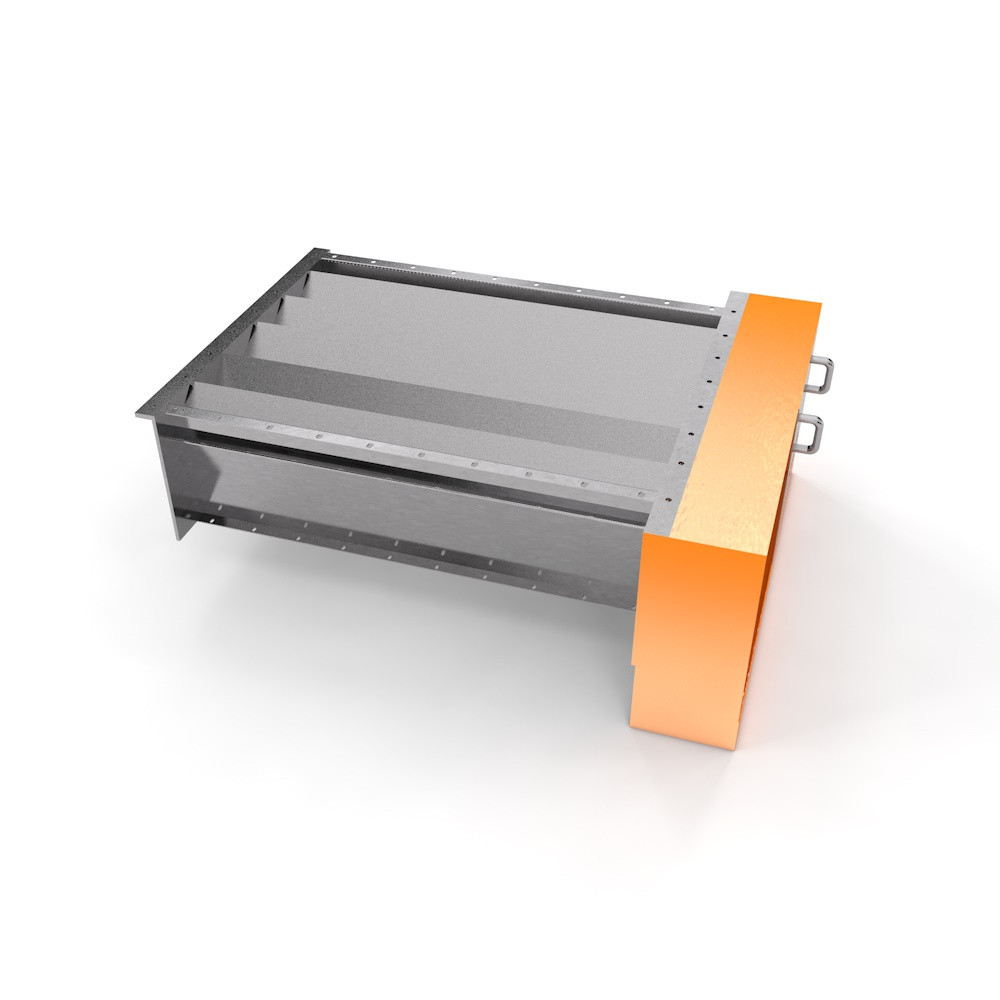

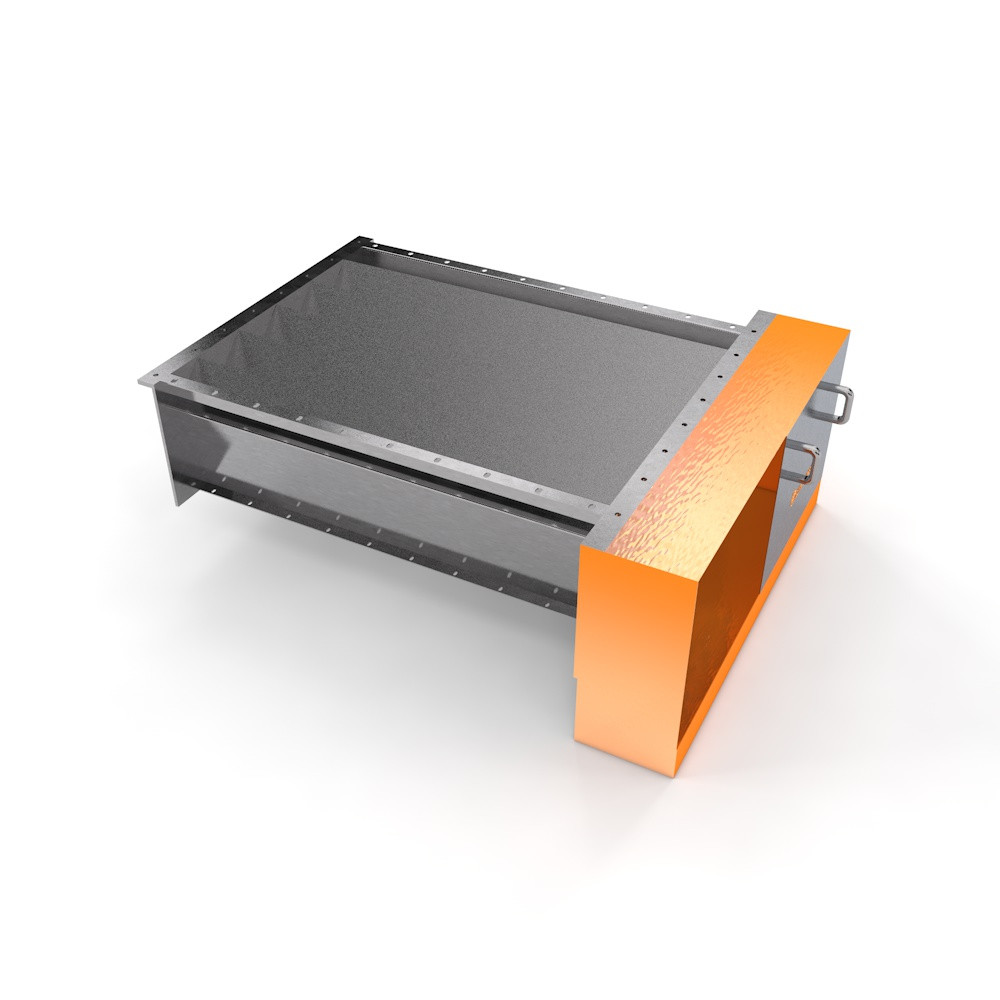

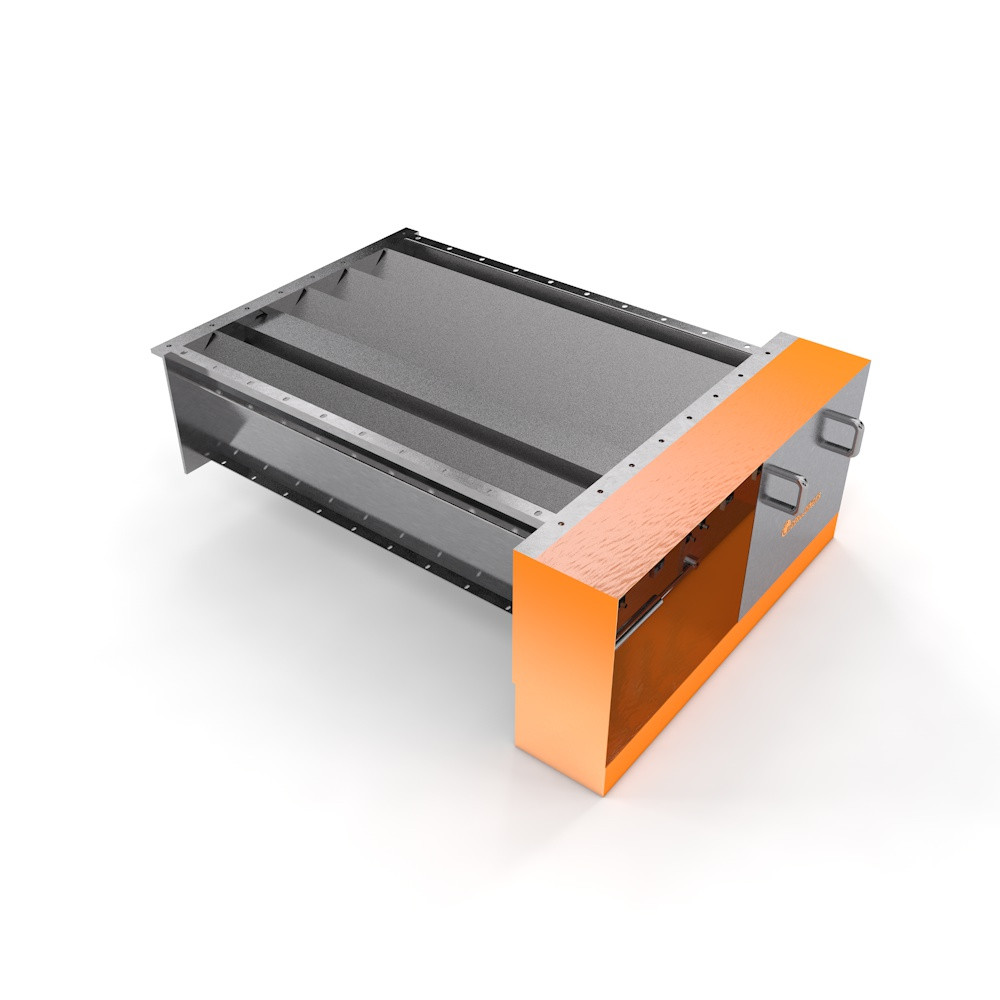

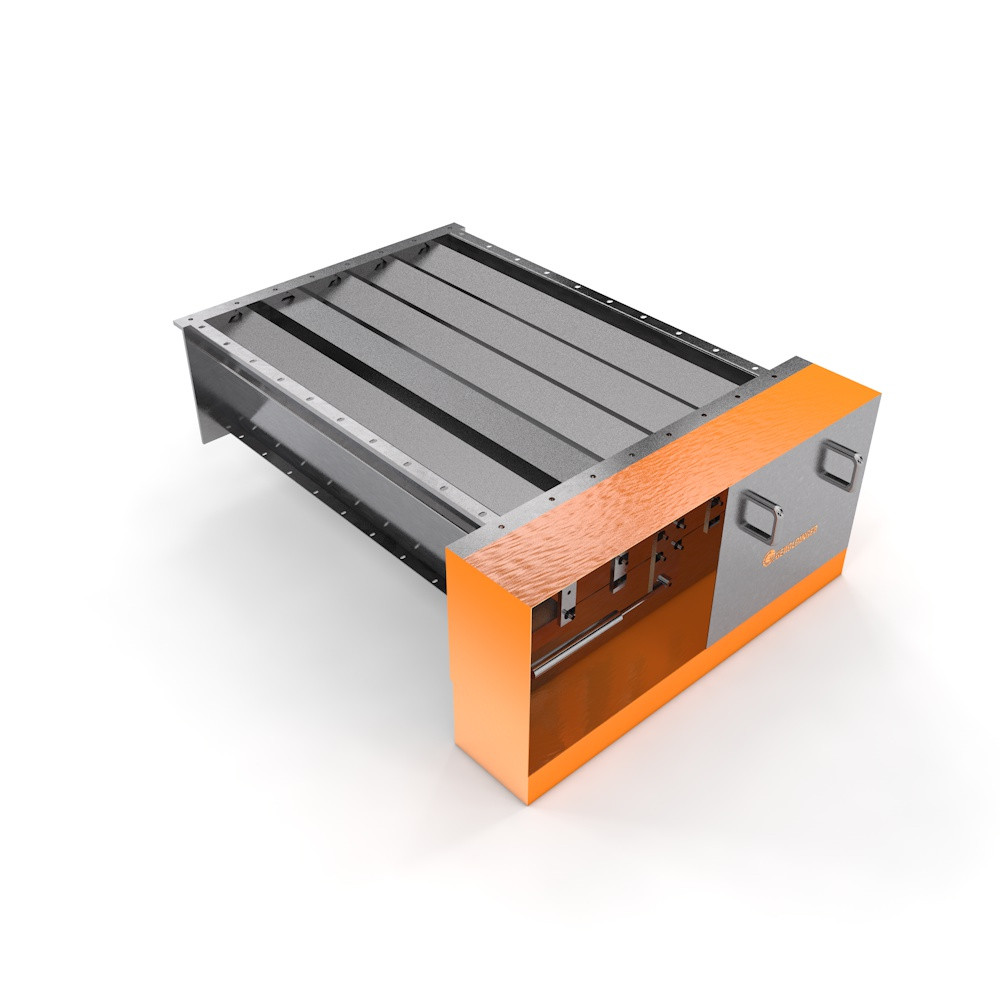

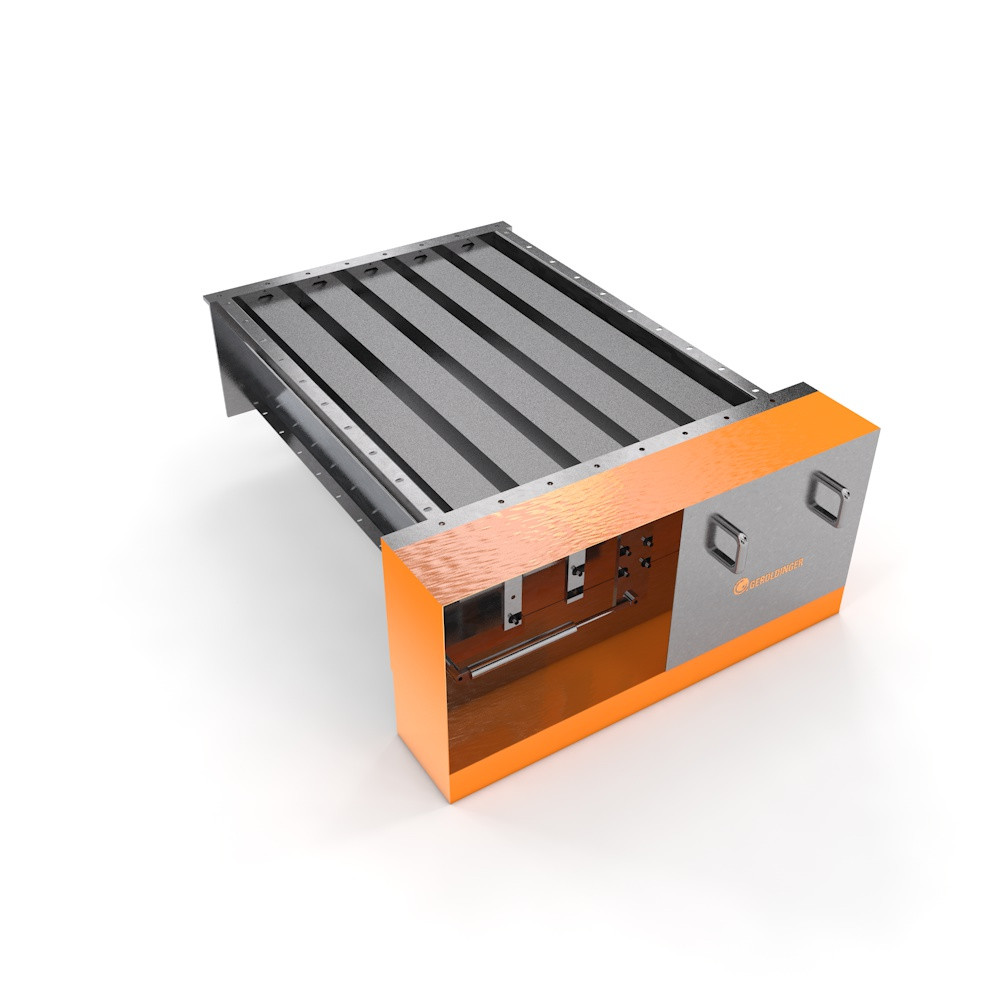

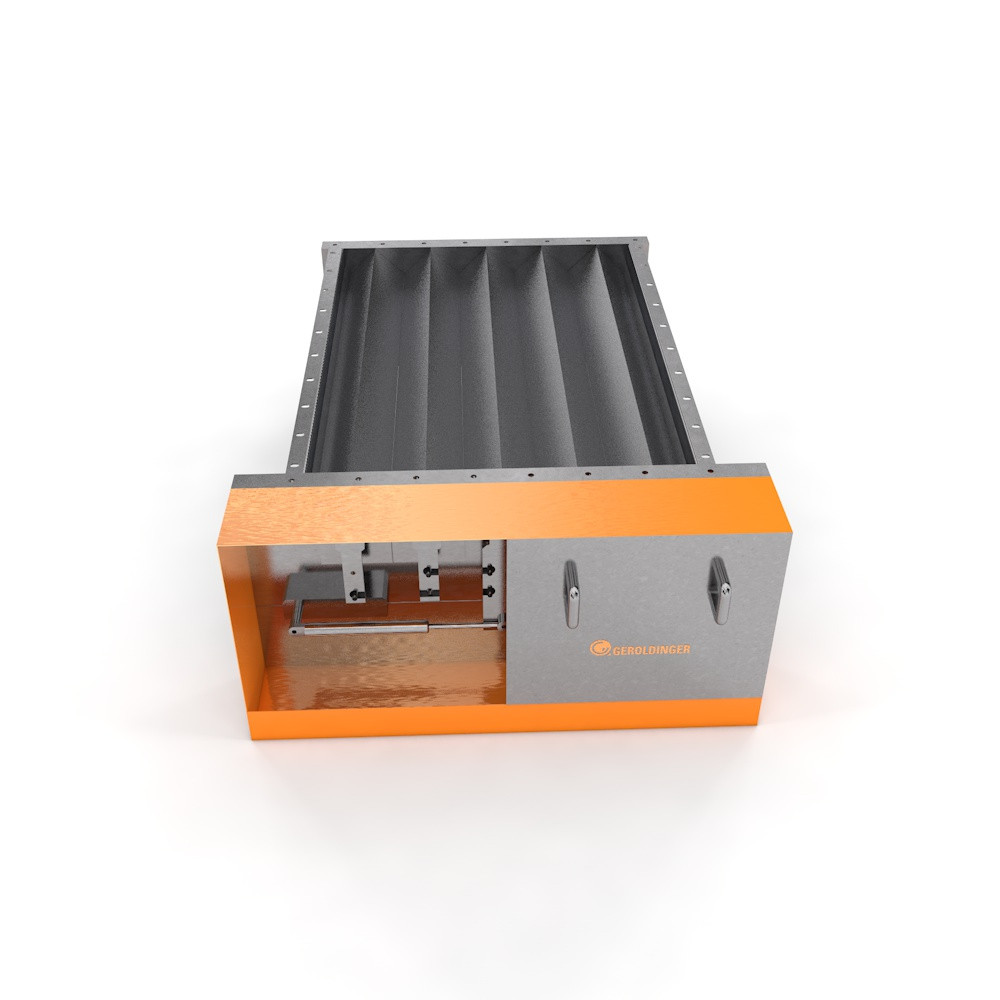

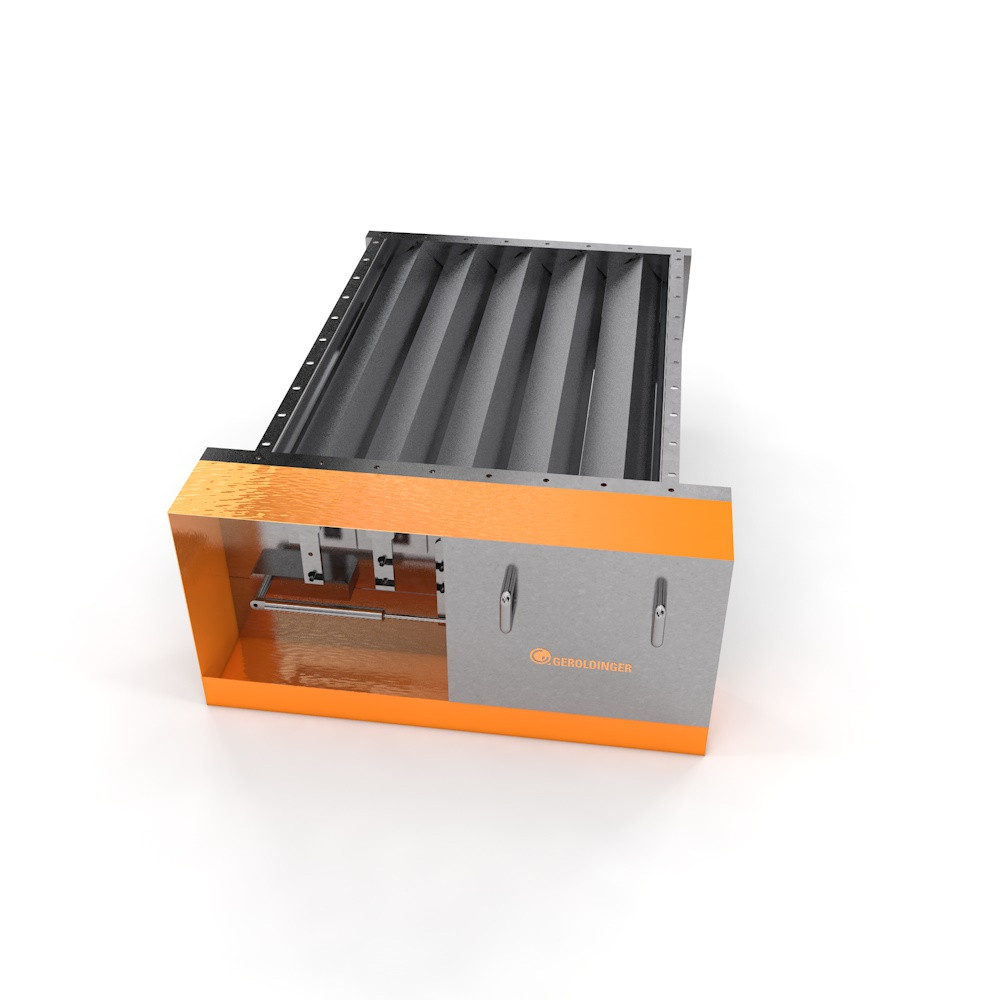

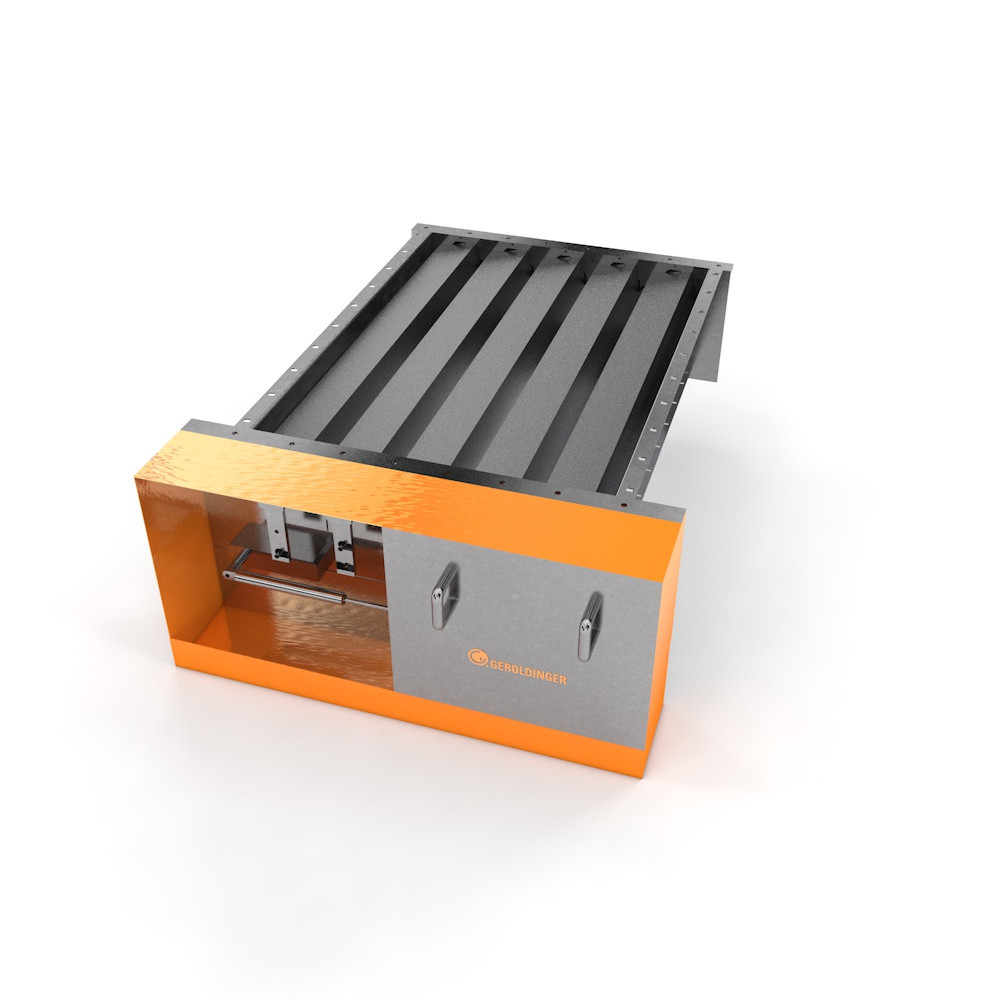

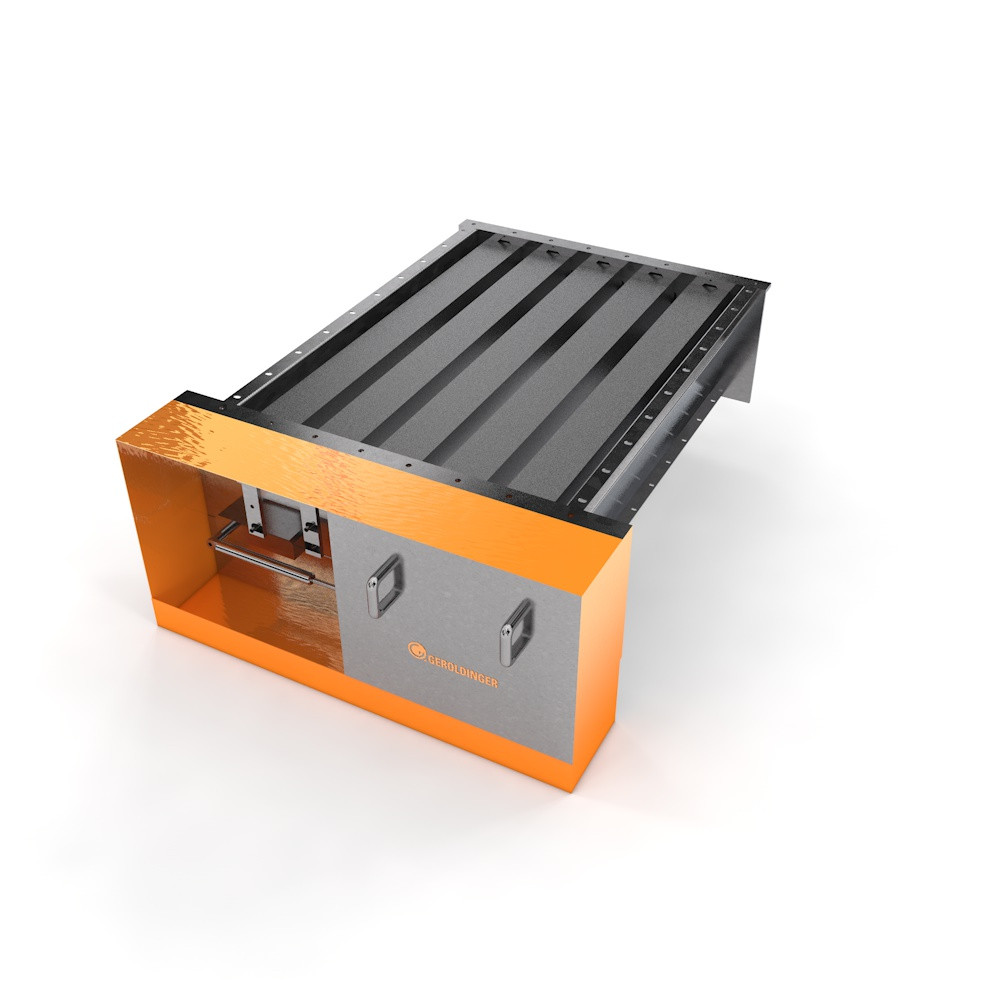

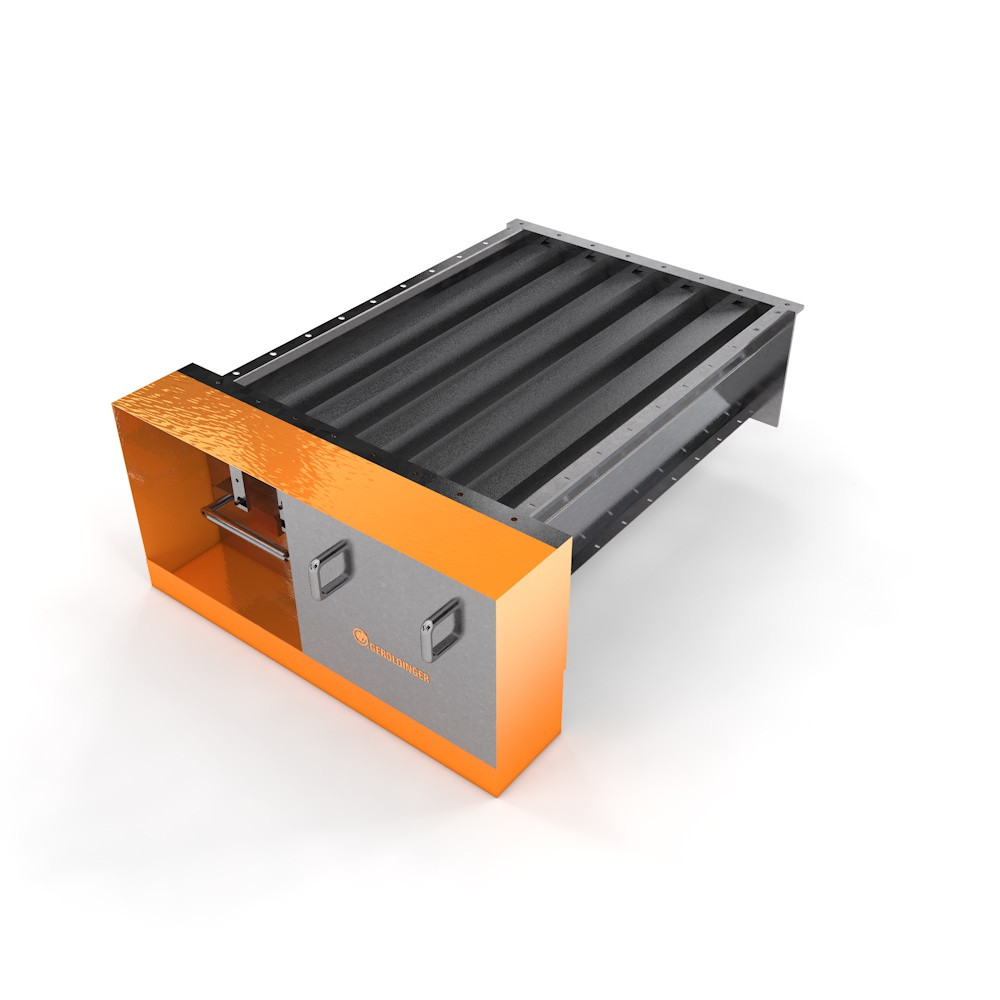

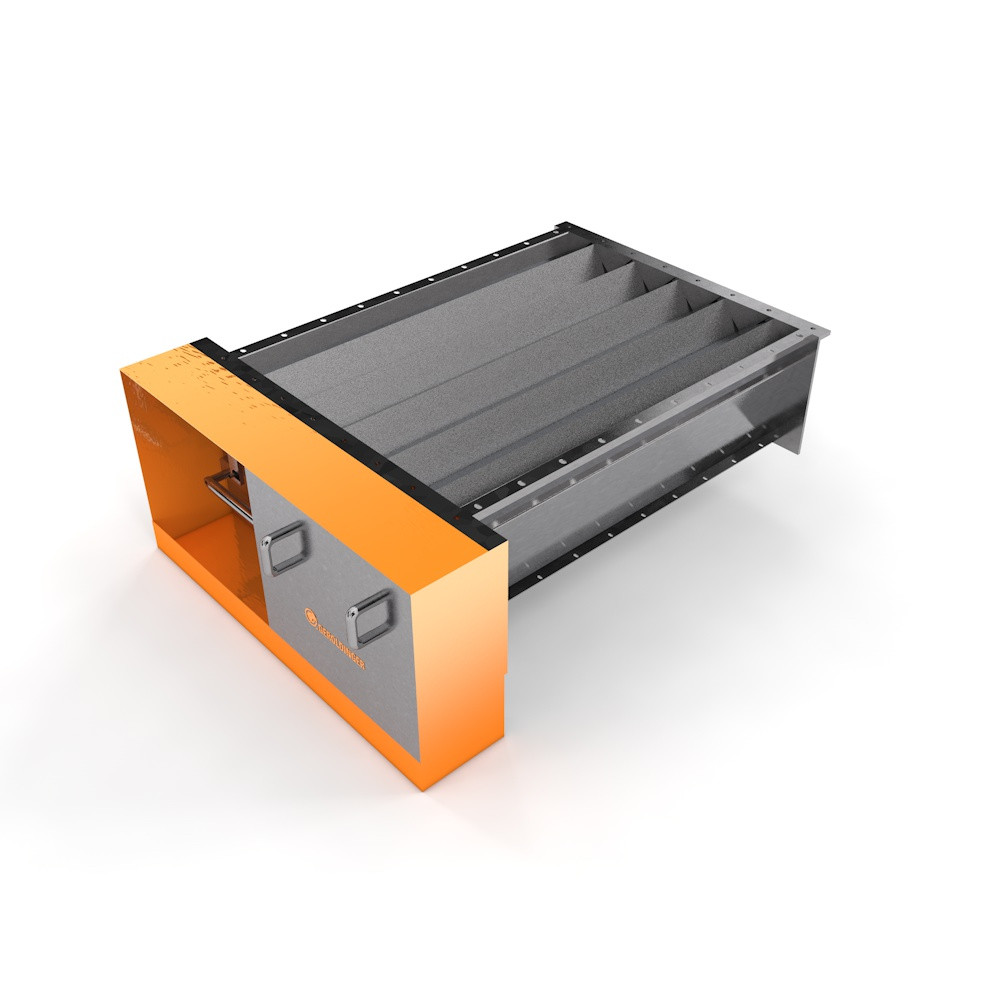

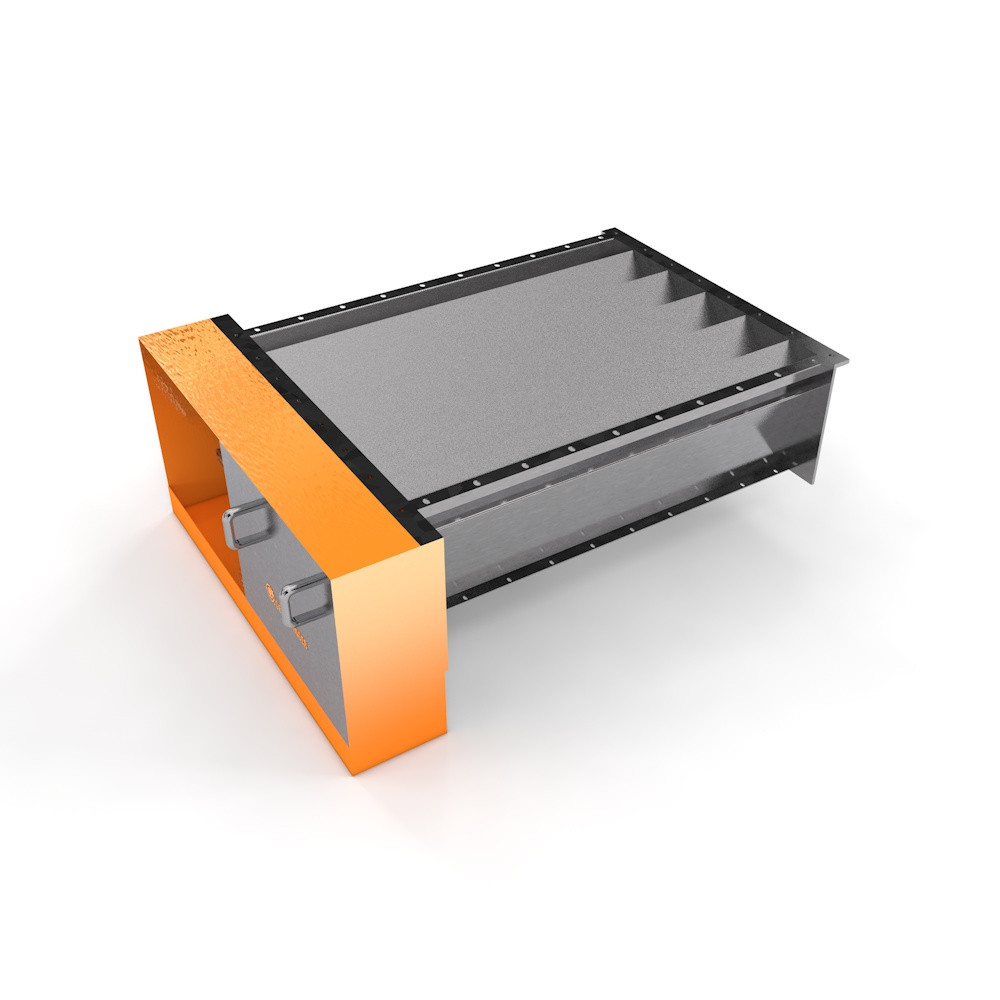

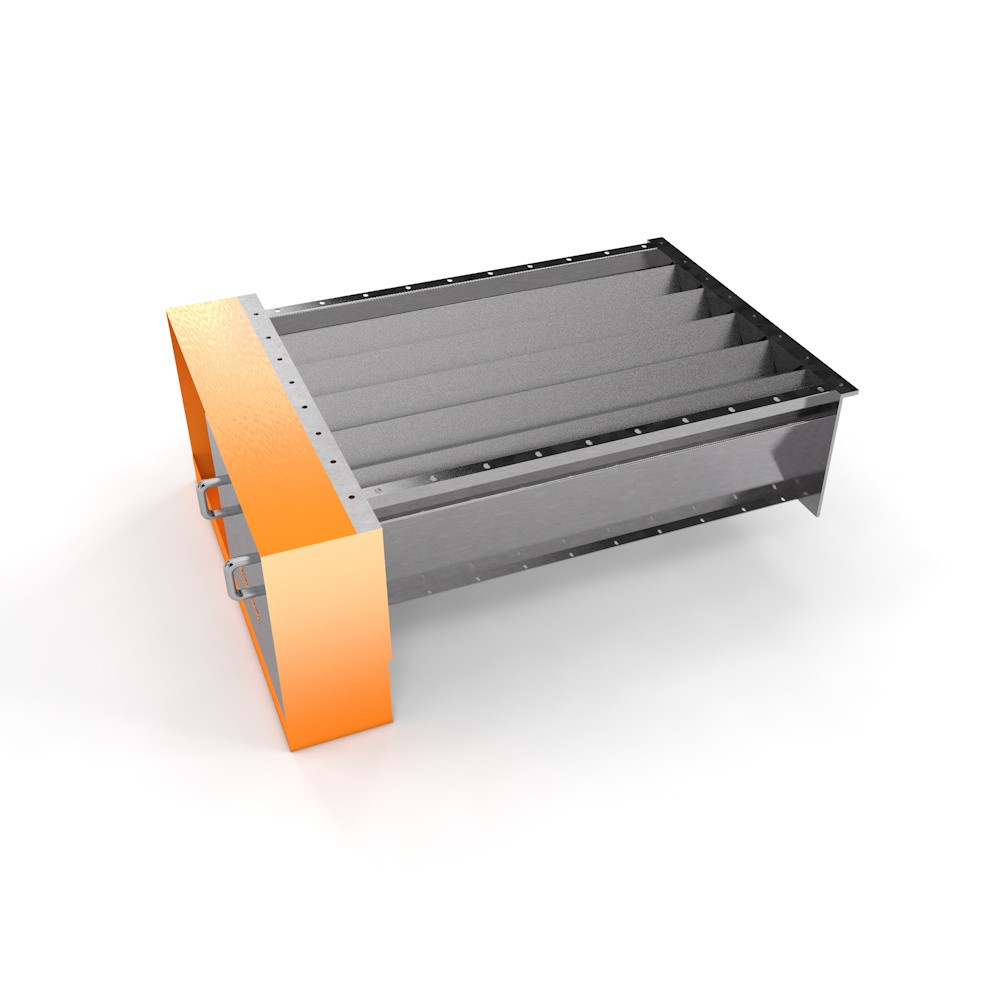

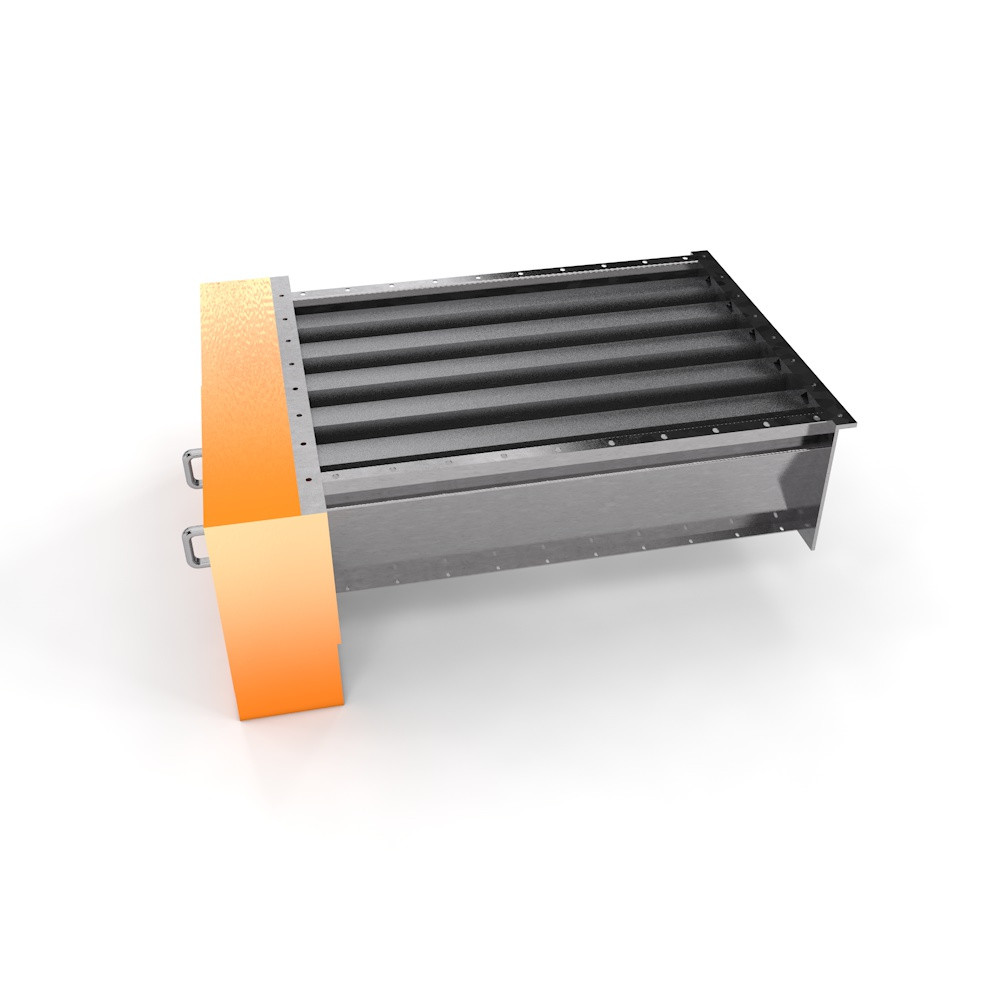

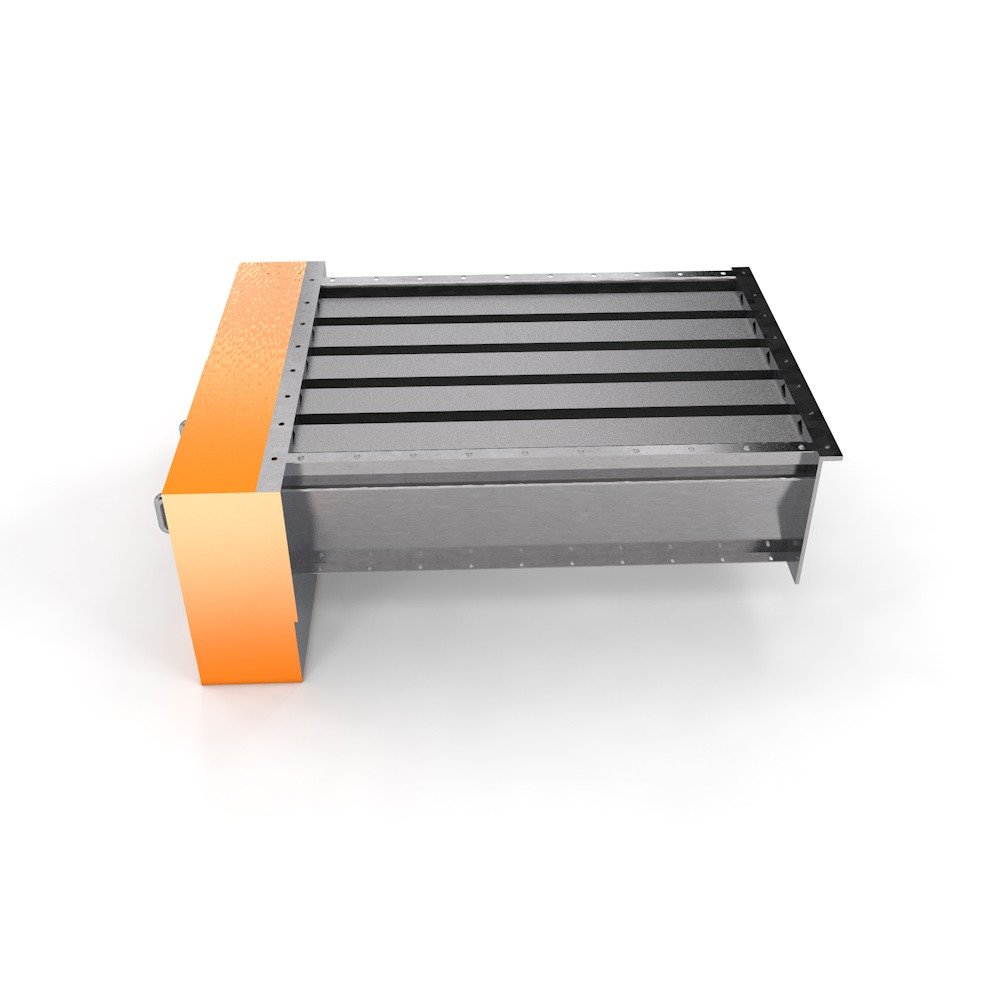

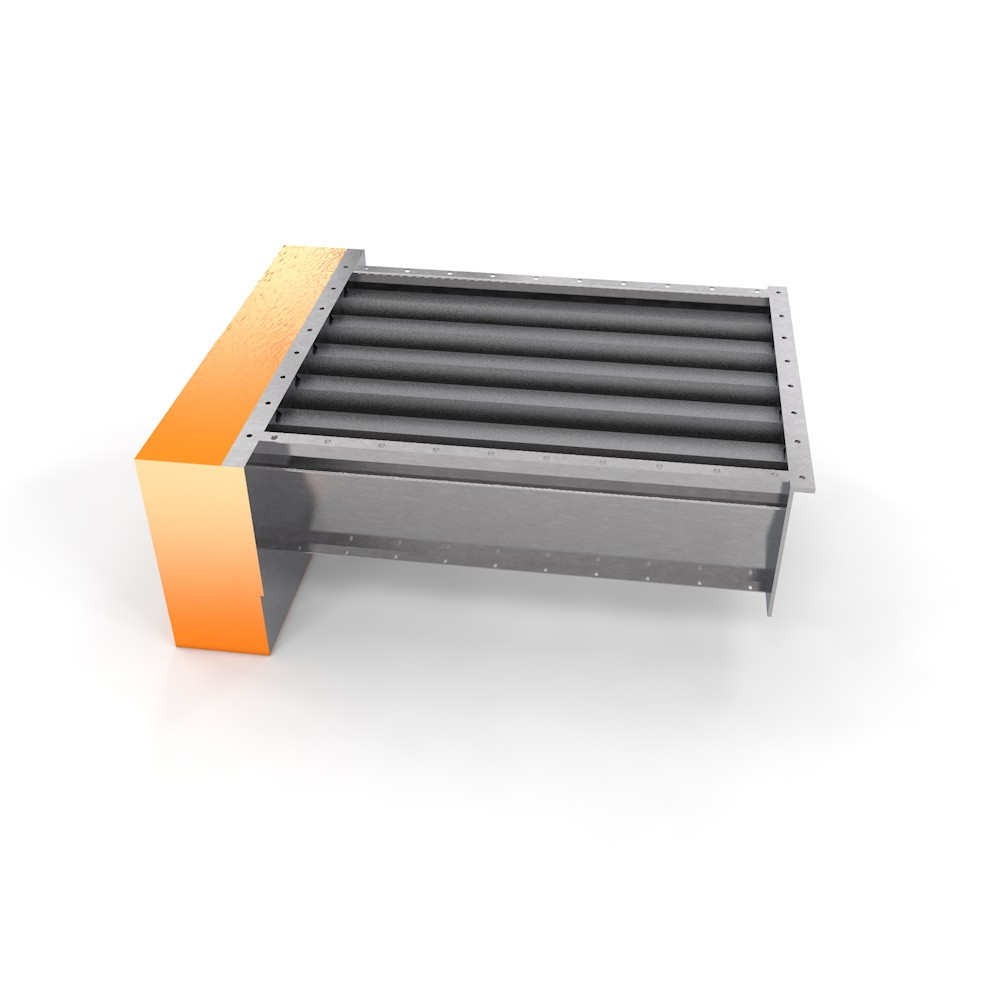

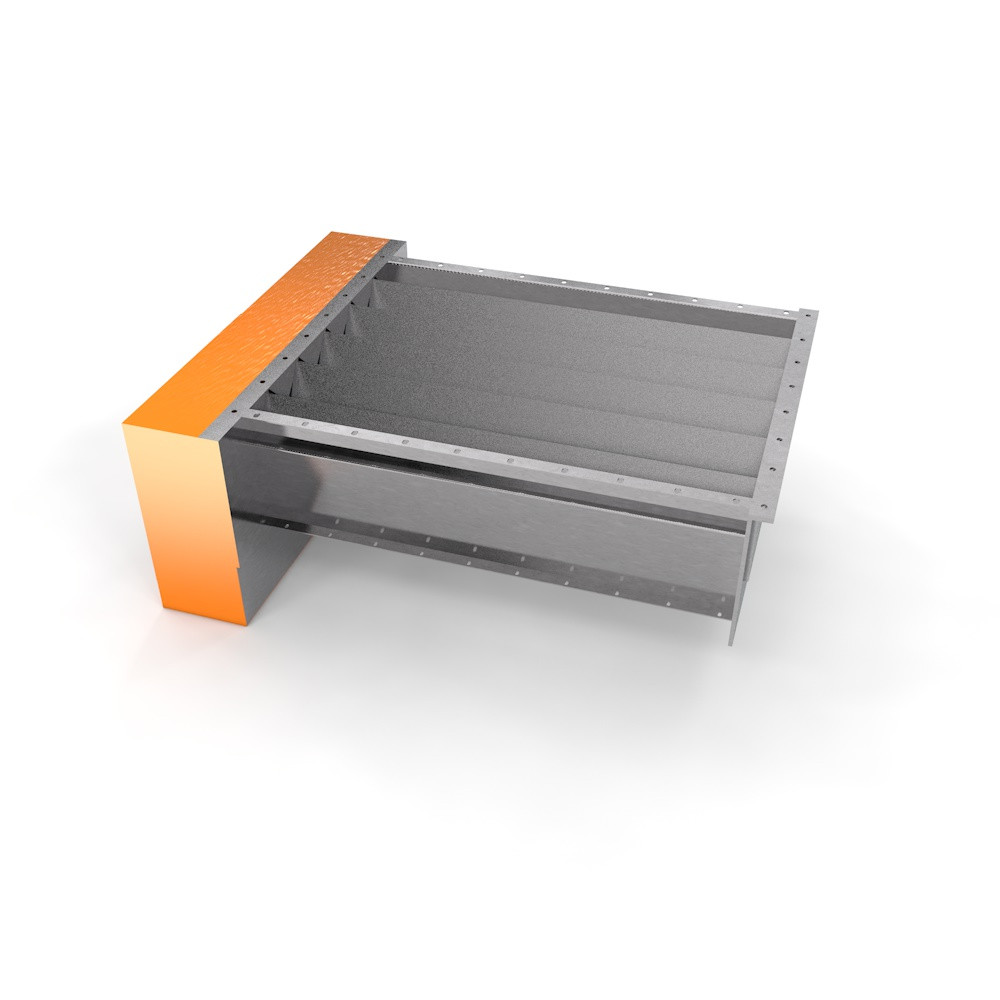

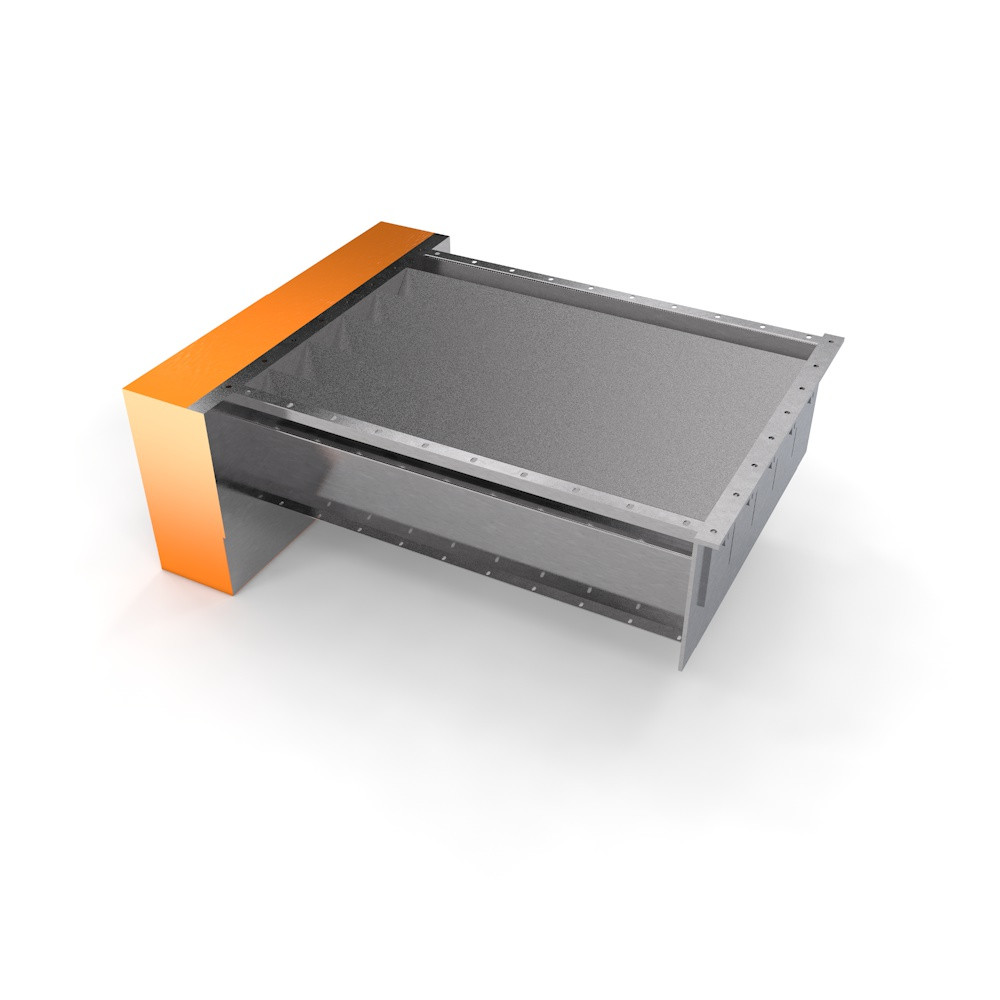

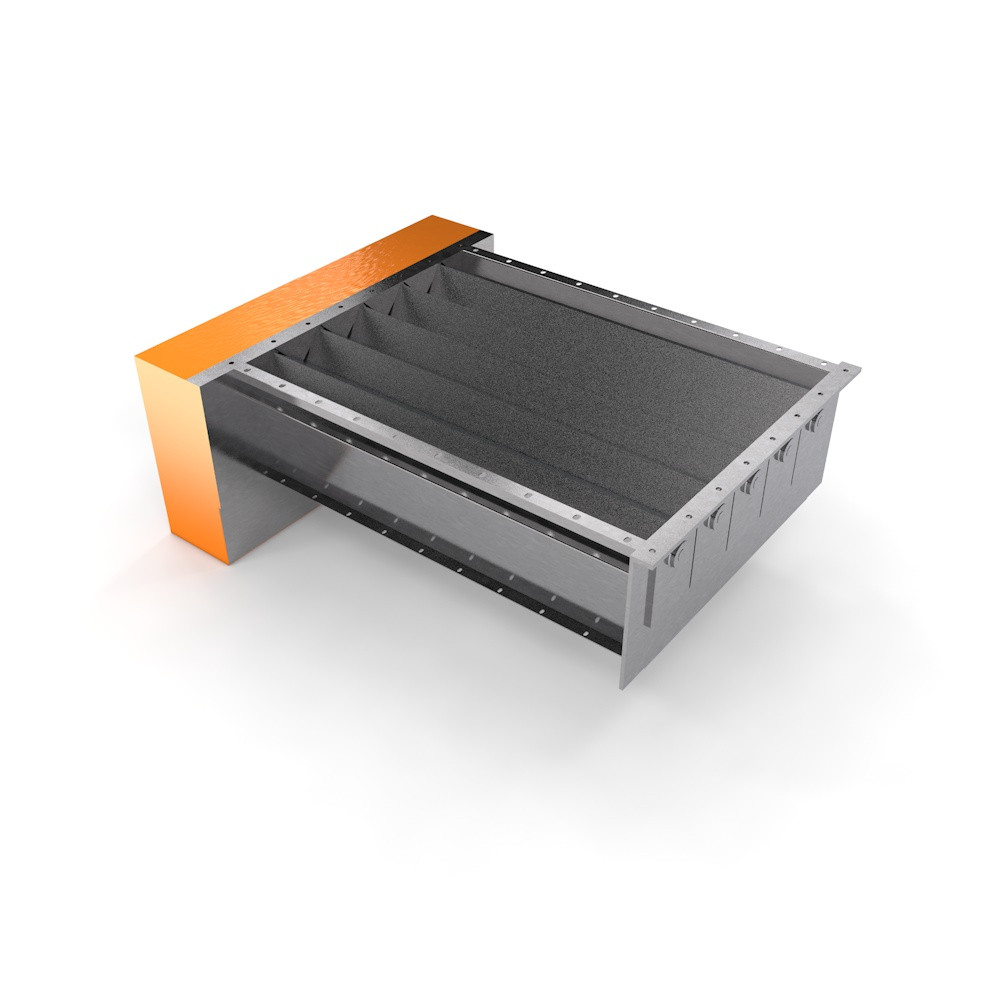

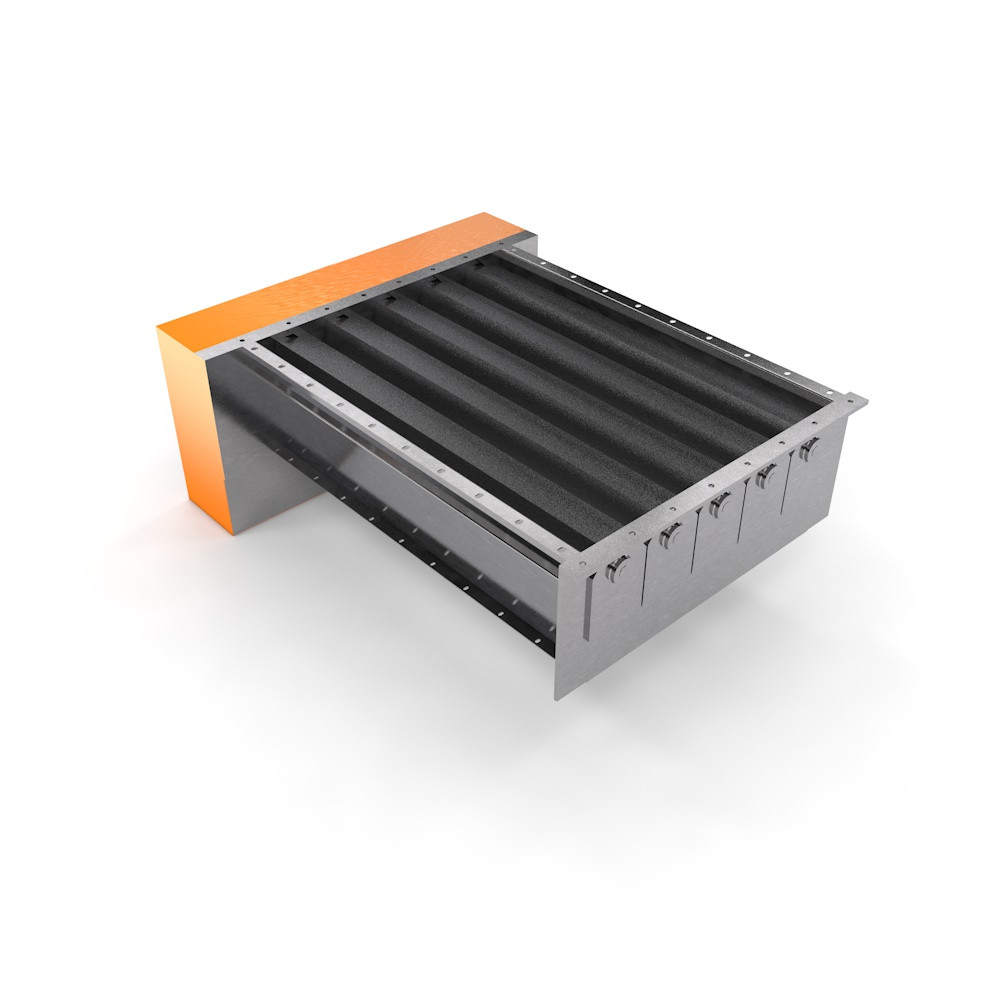

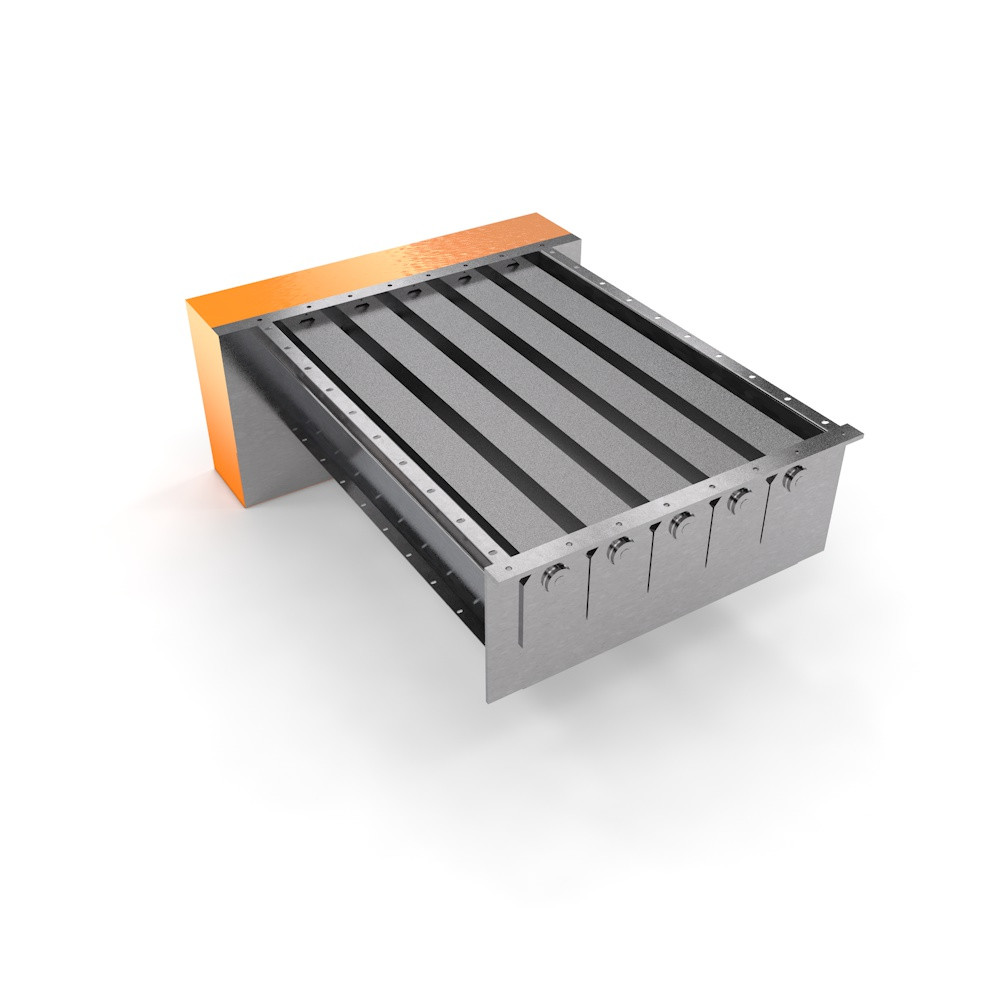

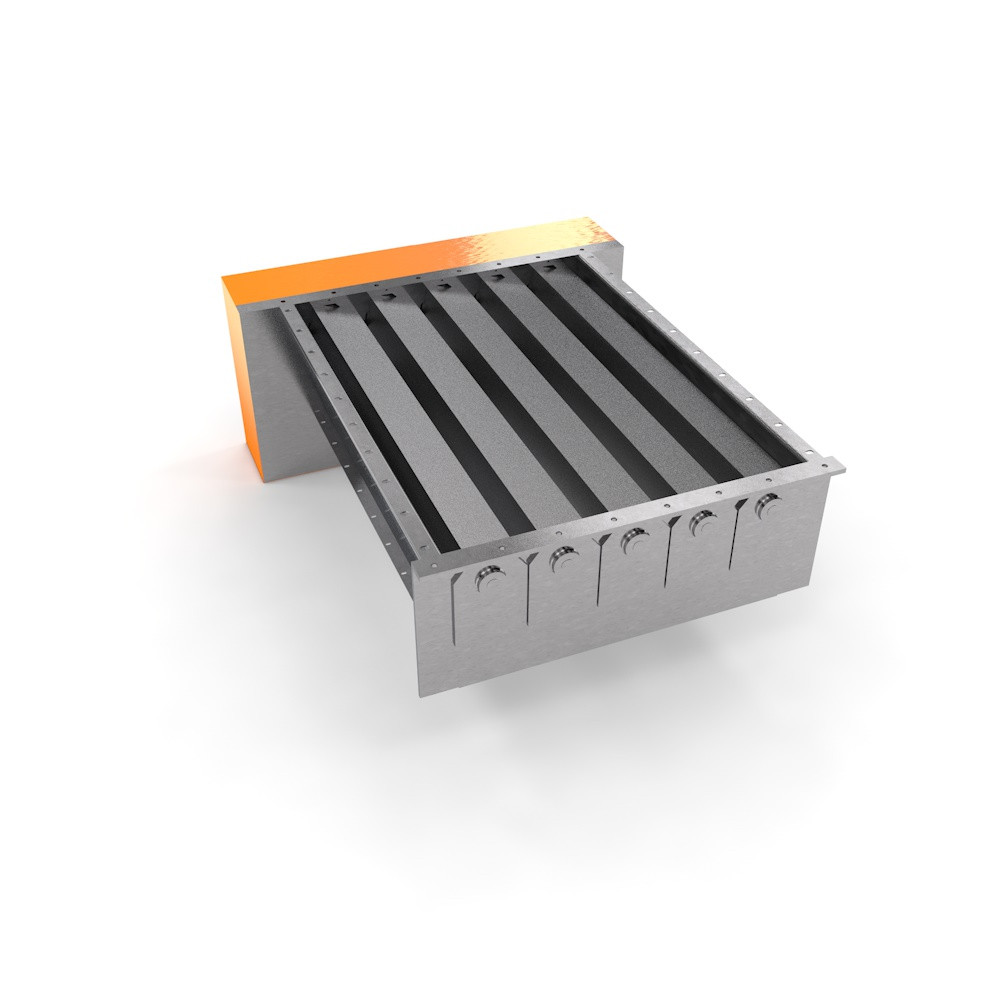

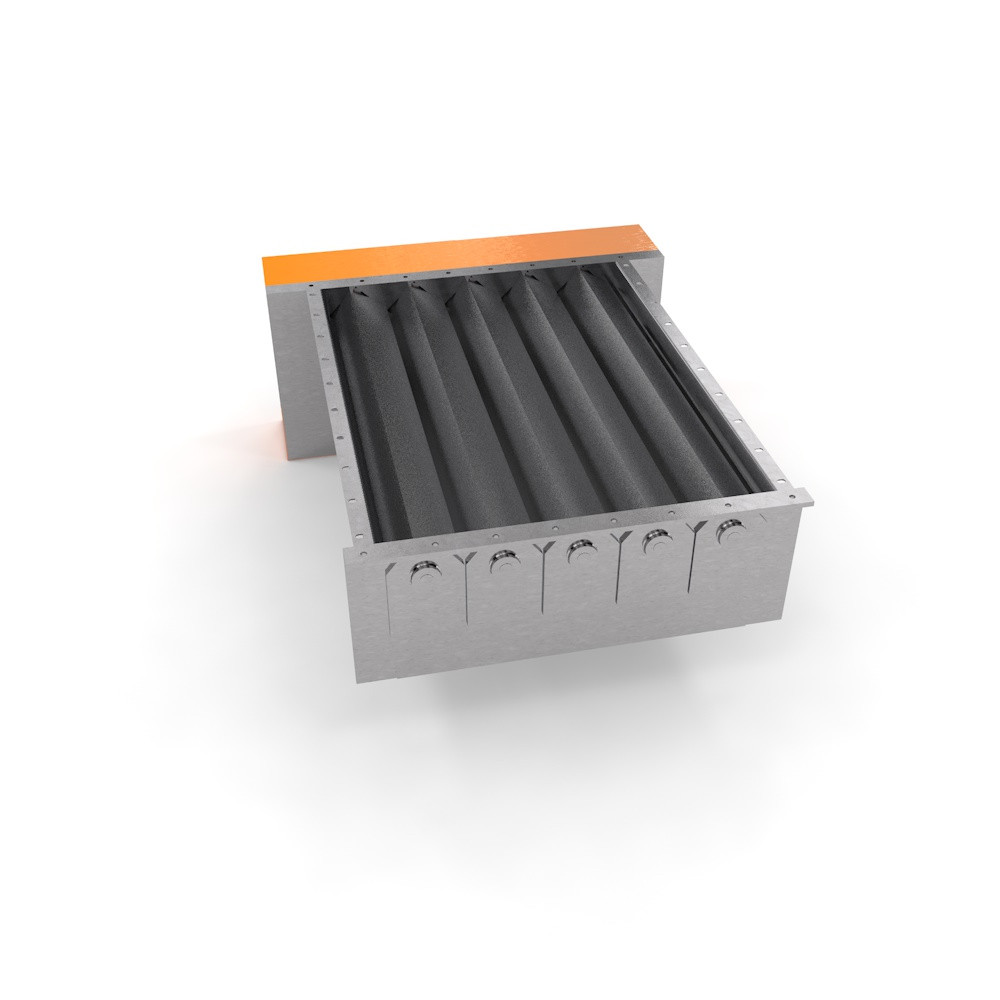

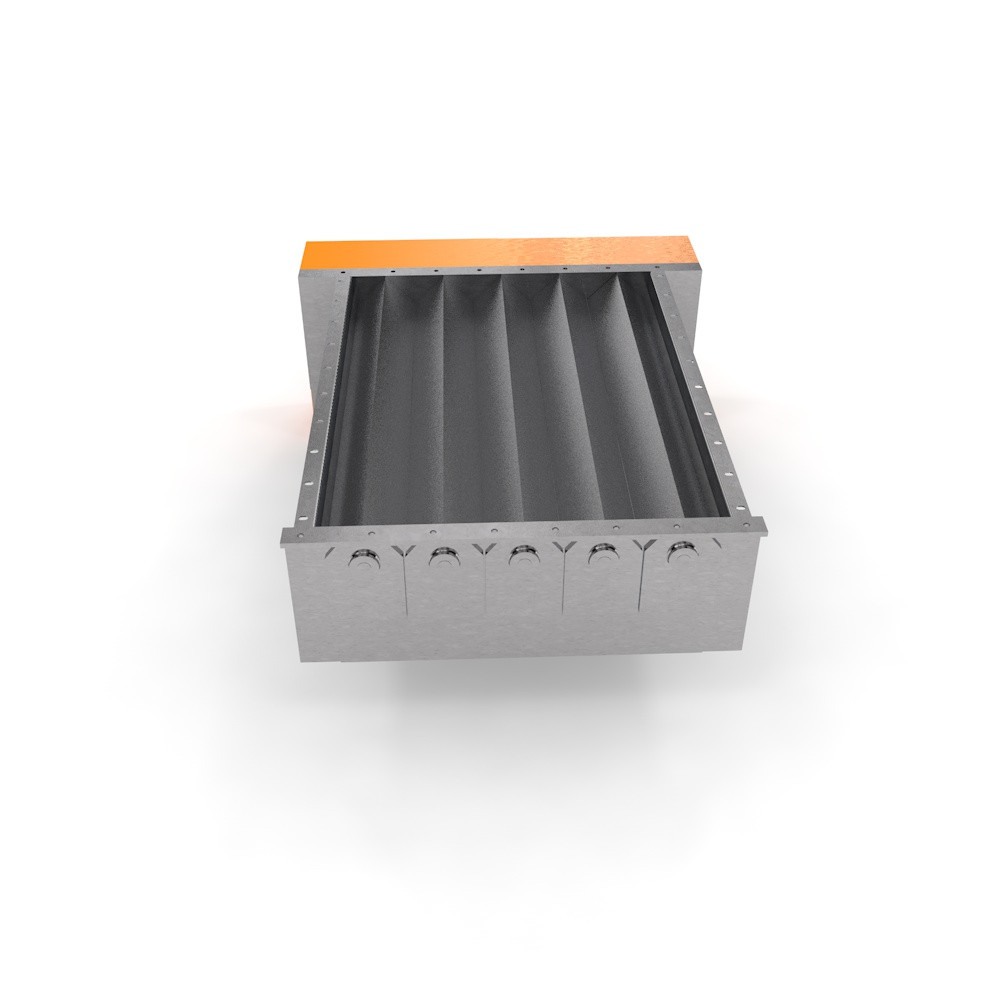

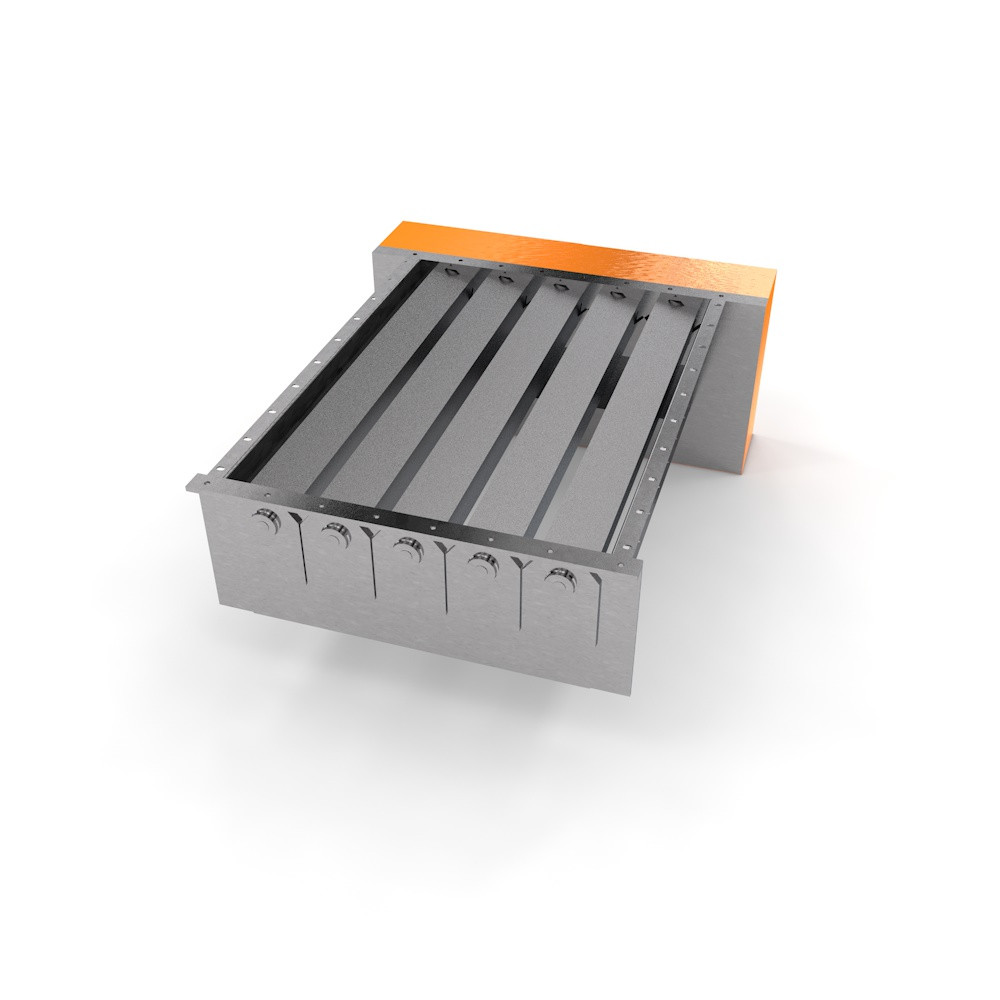

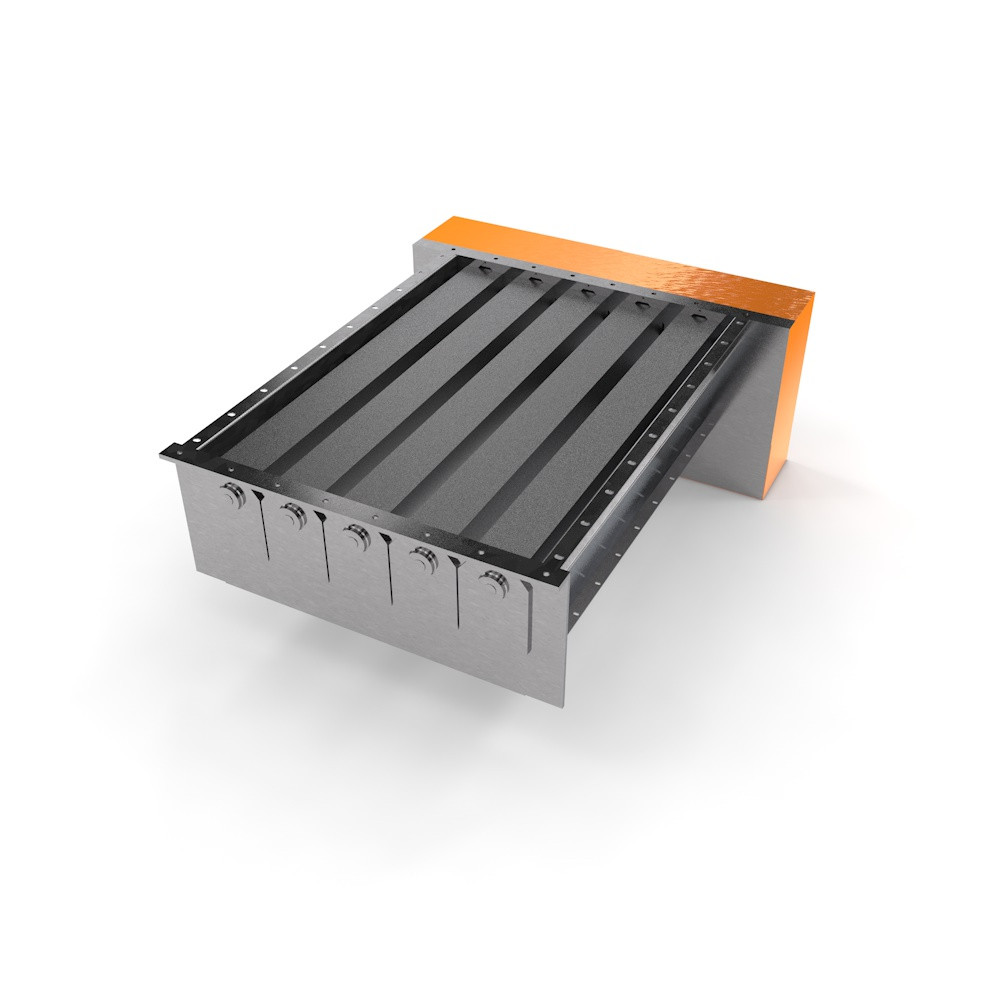

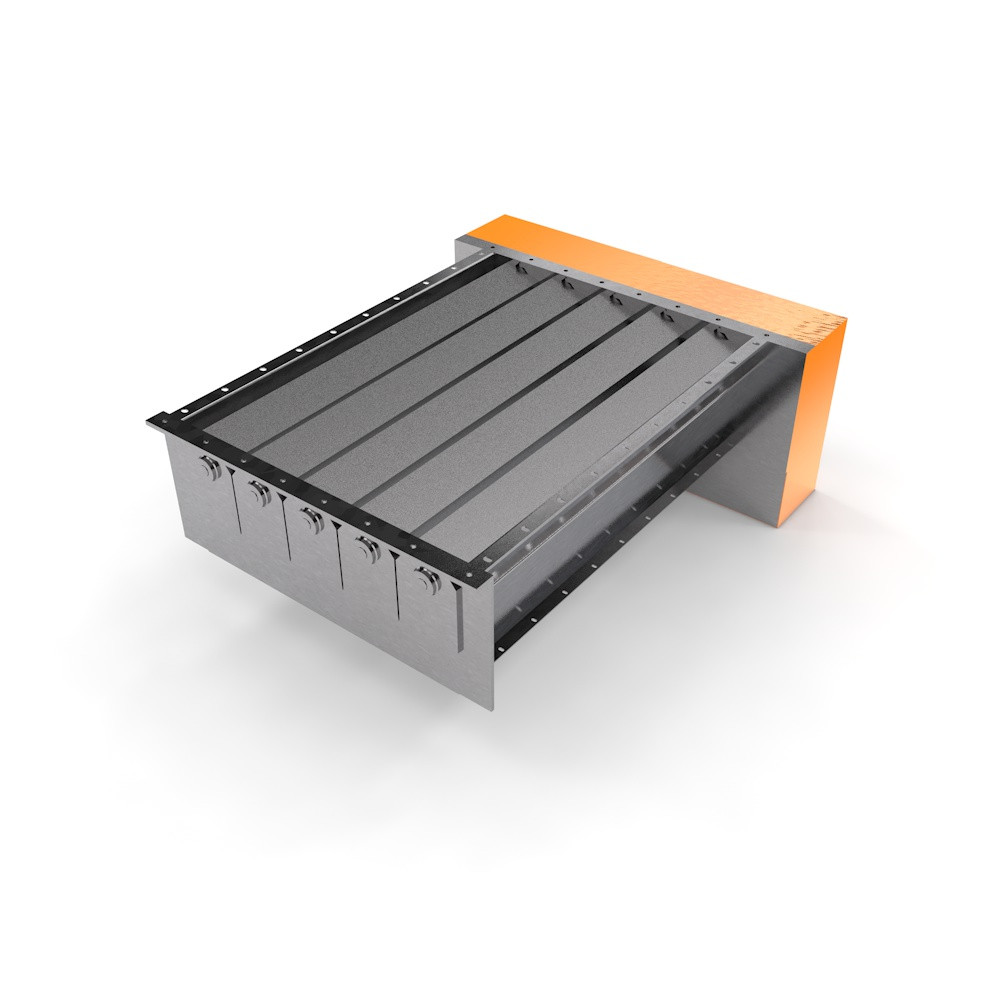

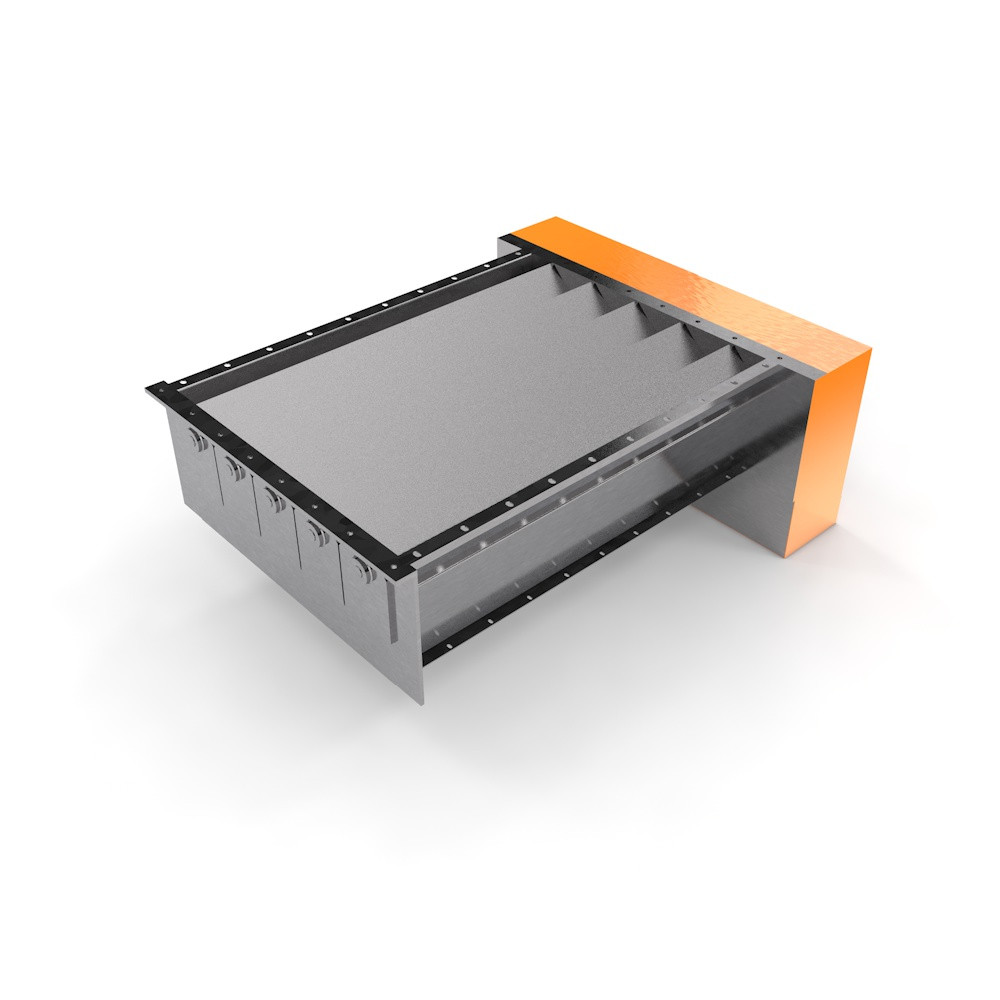

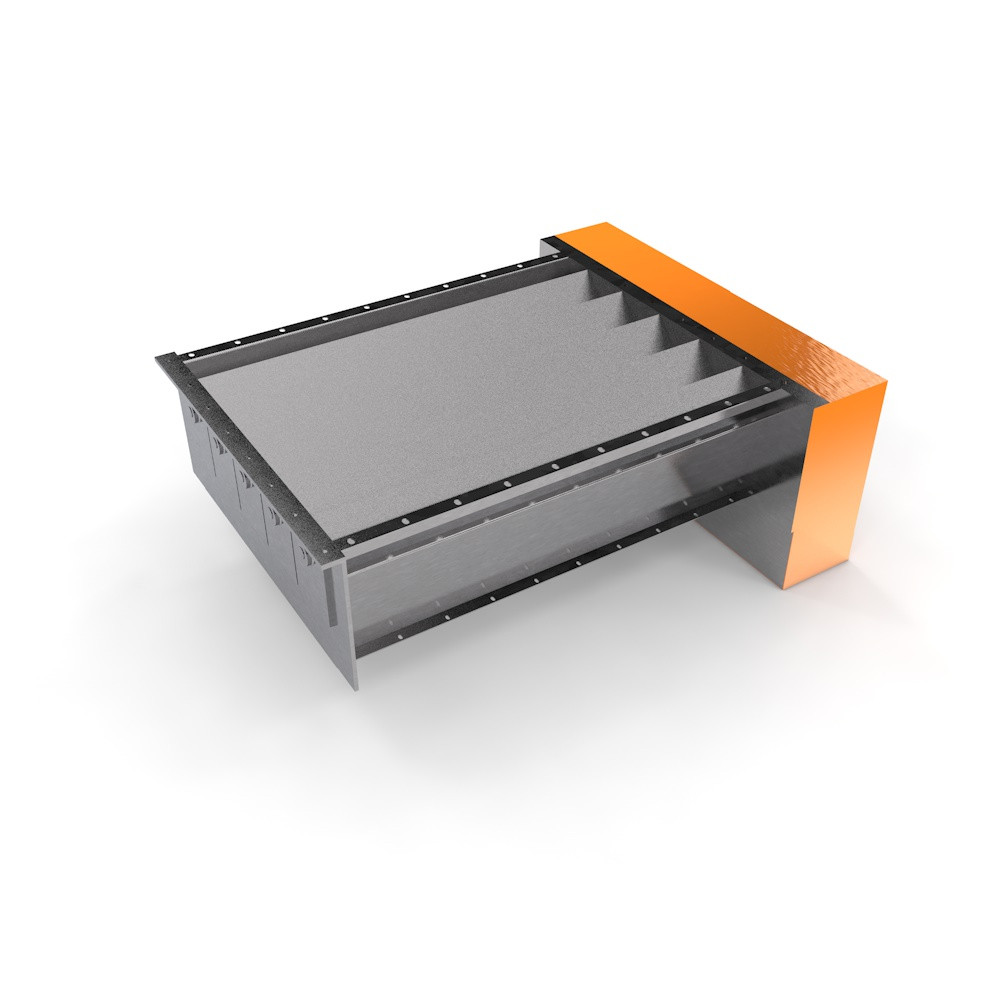

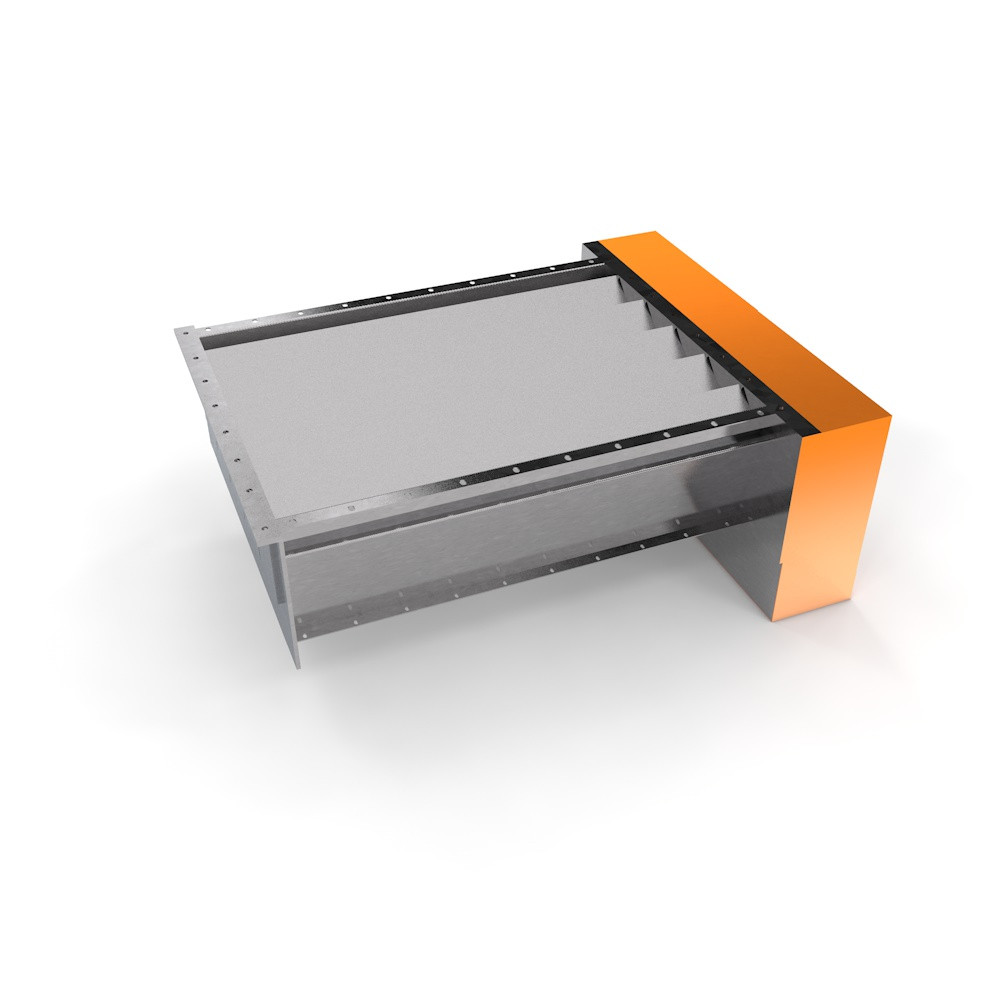

Oszillomat

Applications:

– All bulk goods

– Preferably for very cohesive bulk solids (e.g. melamine)

– Preferably for hygroscopic bulk solids (e.g. urea)

– Preferably for paste-like bulk solids (e.g. filter cakes)

– Preferably for non-liquid bulk solids (e.g. foil chips)

Advantages:

– Safe mass flow

– High dosing consistency

– Does not destroy the bulk solids (brittle bulk solids)

– Occuring lumps that might cause problems are destroyed

(hygroscopic bulk solids)

– All bearing components are located externally

– Comparably low drive output

– Safe startup of the discharge including with high pressure on the ground

(large silo)

Technical Details:

– Discharge cross-section: 0.65 x 0.65 to 4.6 x 4.6 m

– Discharge capacity: < 600 m³/h

– Hydraulic drive

Materials:

– – Regular steel S235 painted (< 480 µm) (< 480 µm)

– Stainless steel 1.4301

– Stainless steel 1.4571

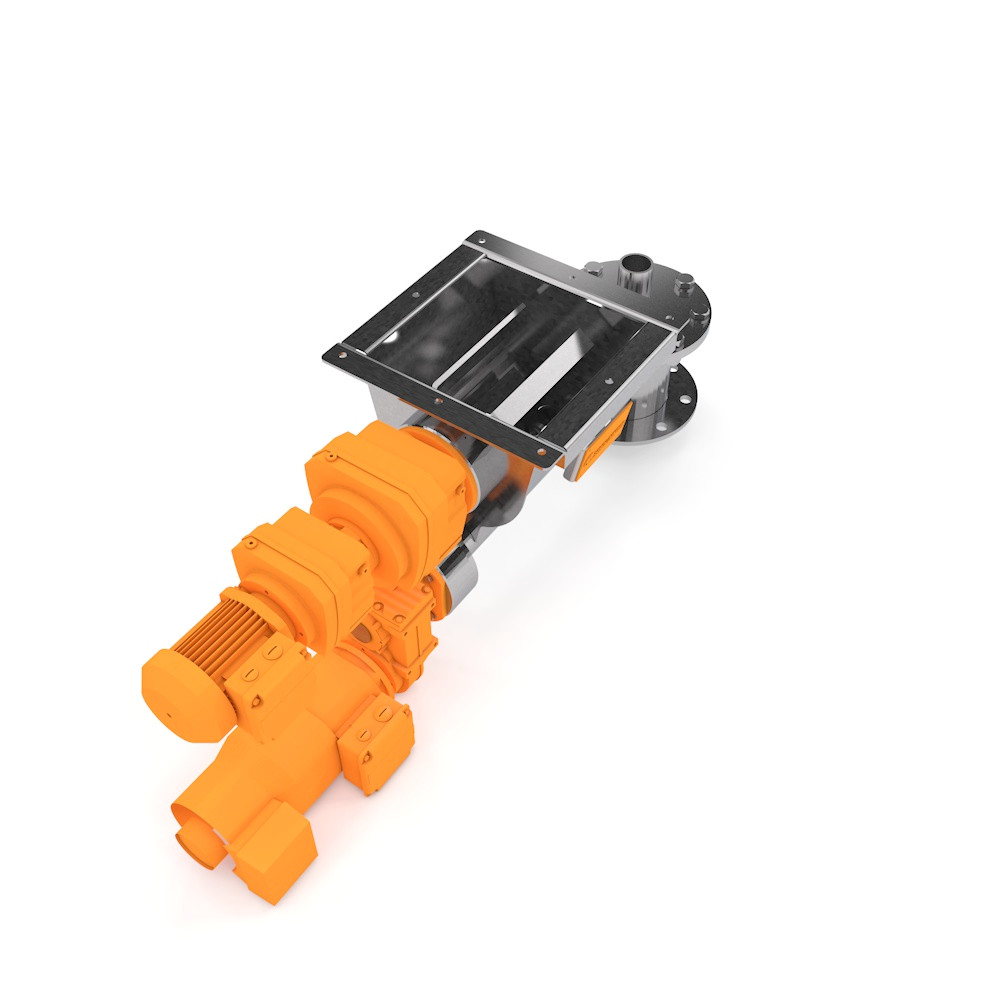

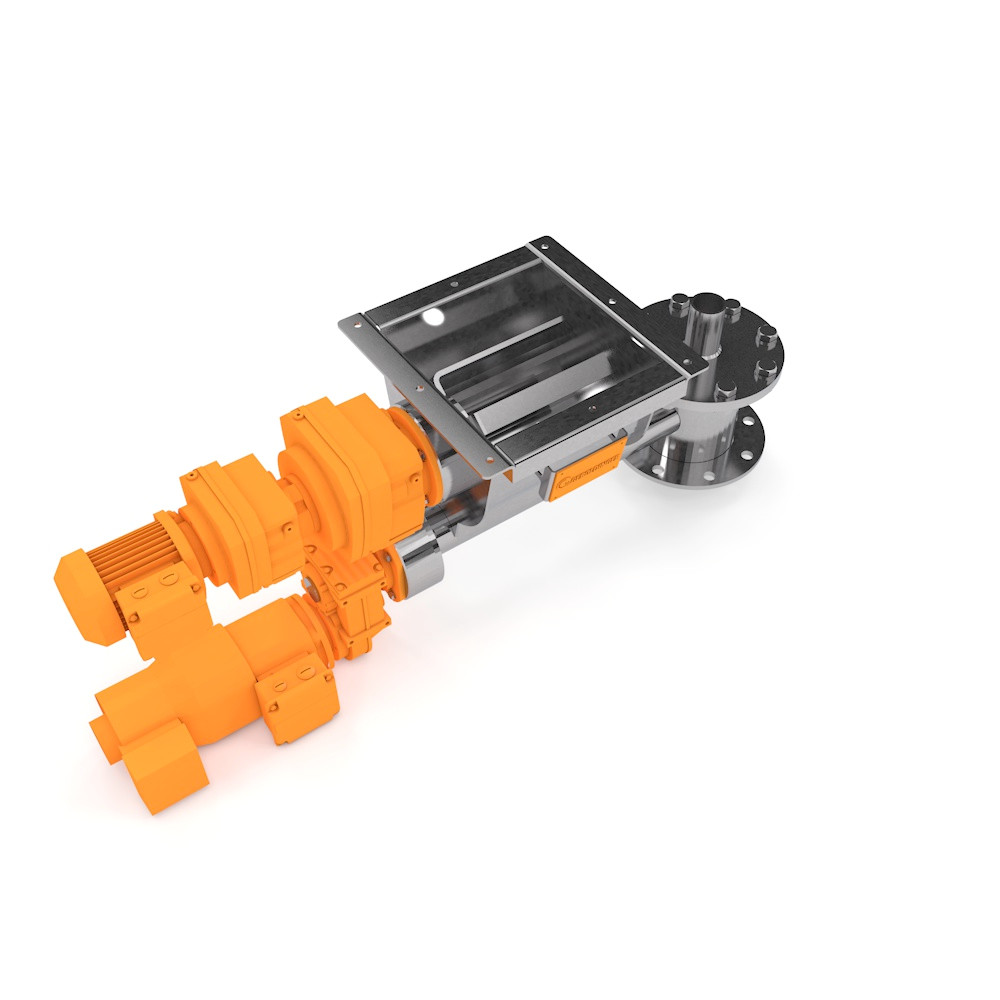

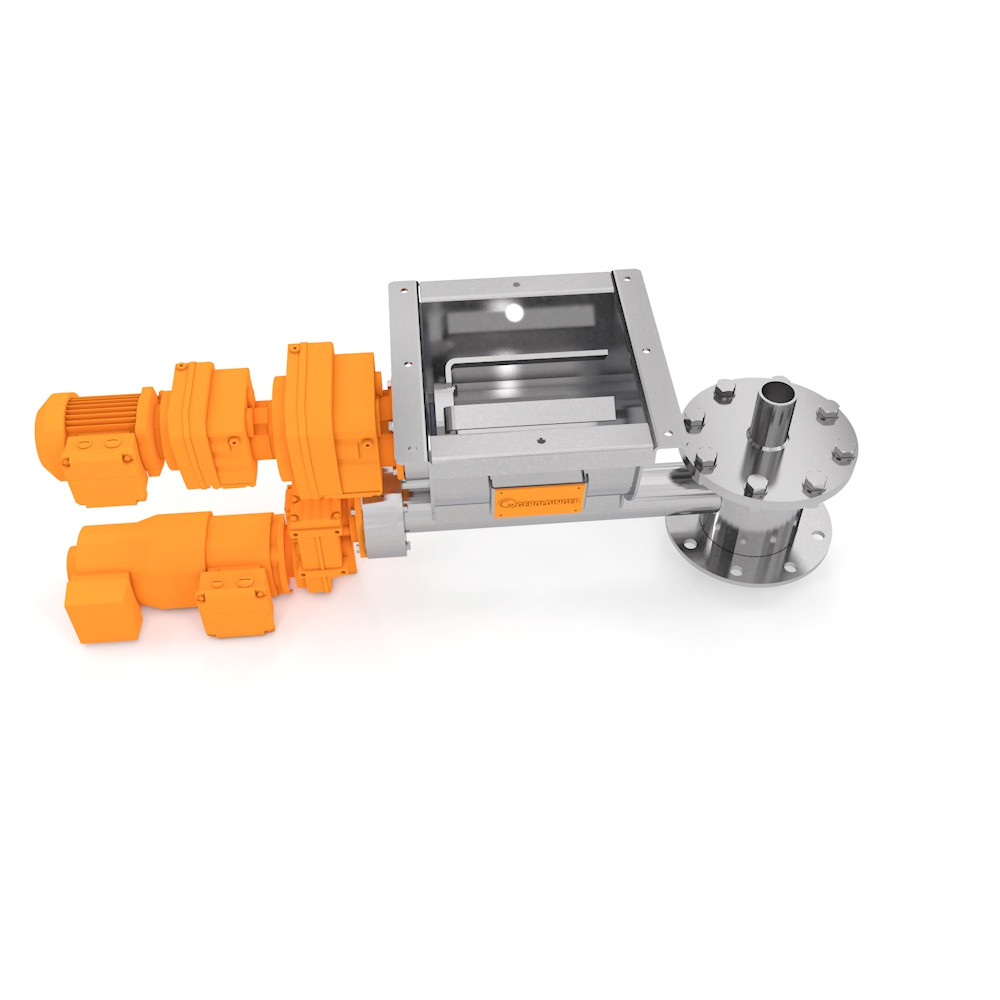

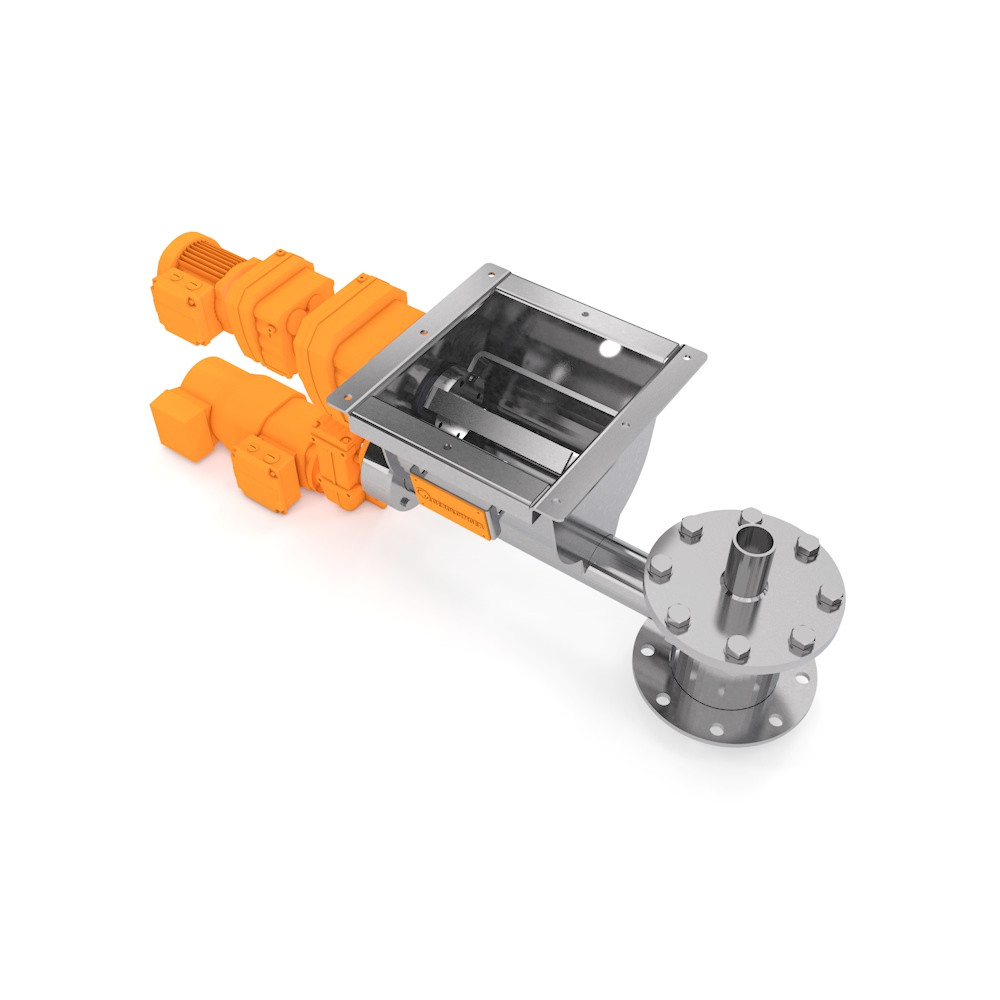

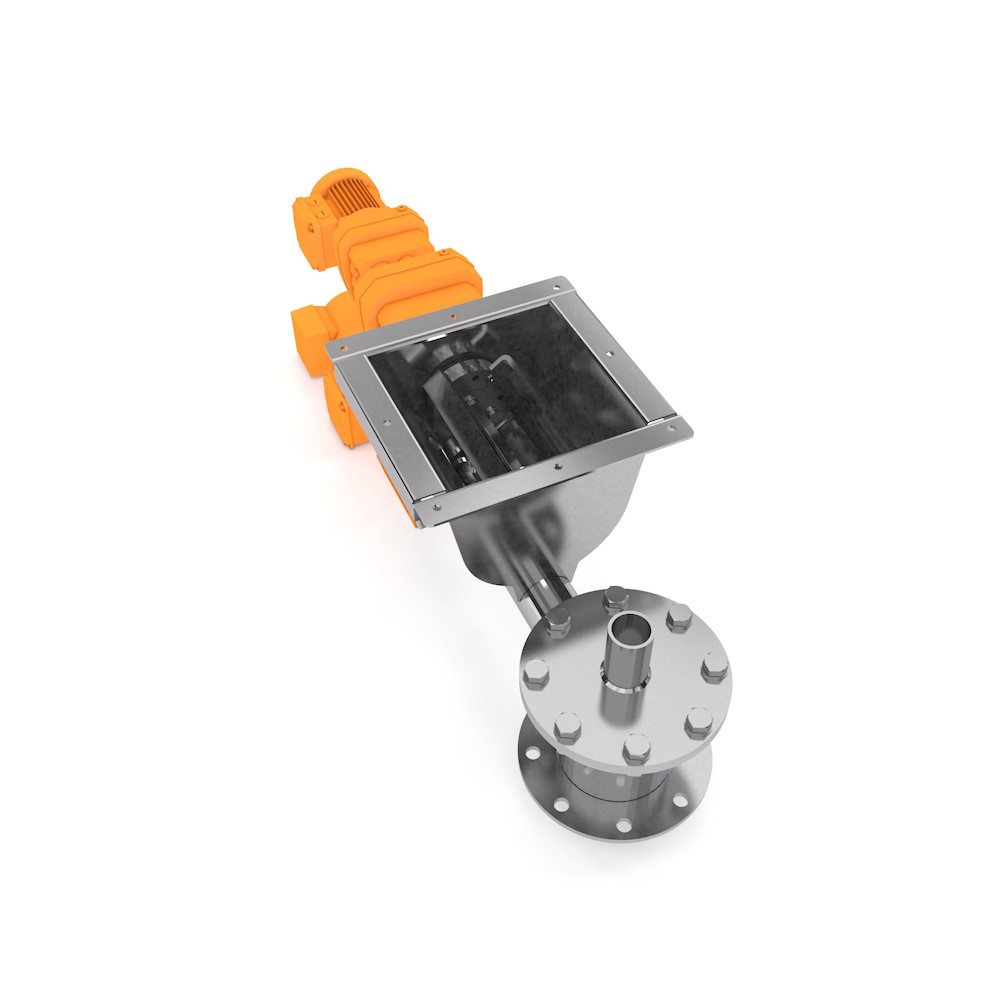

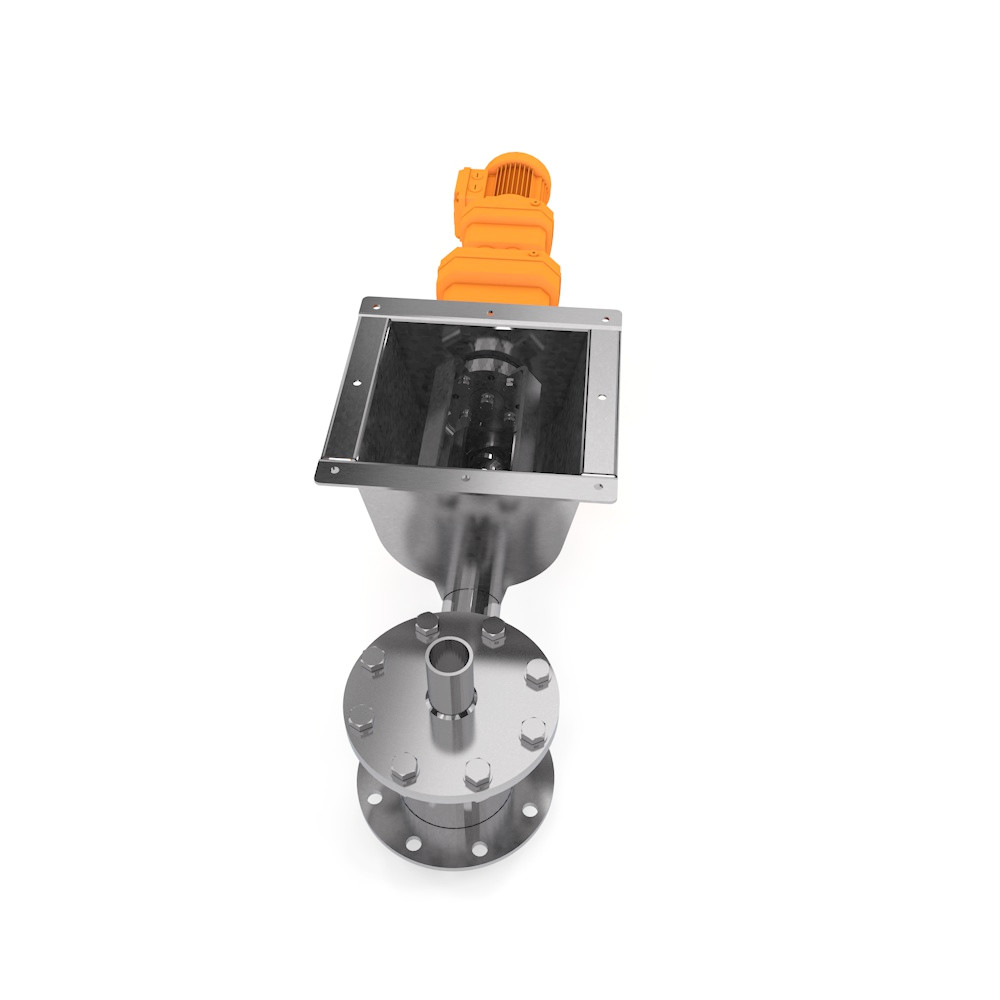

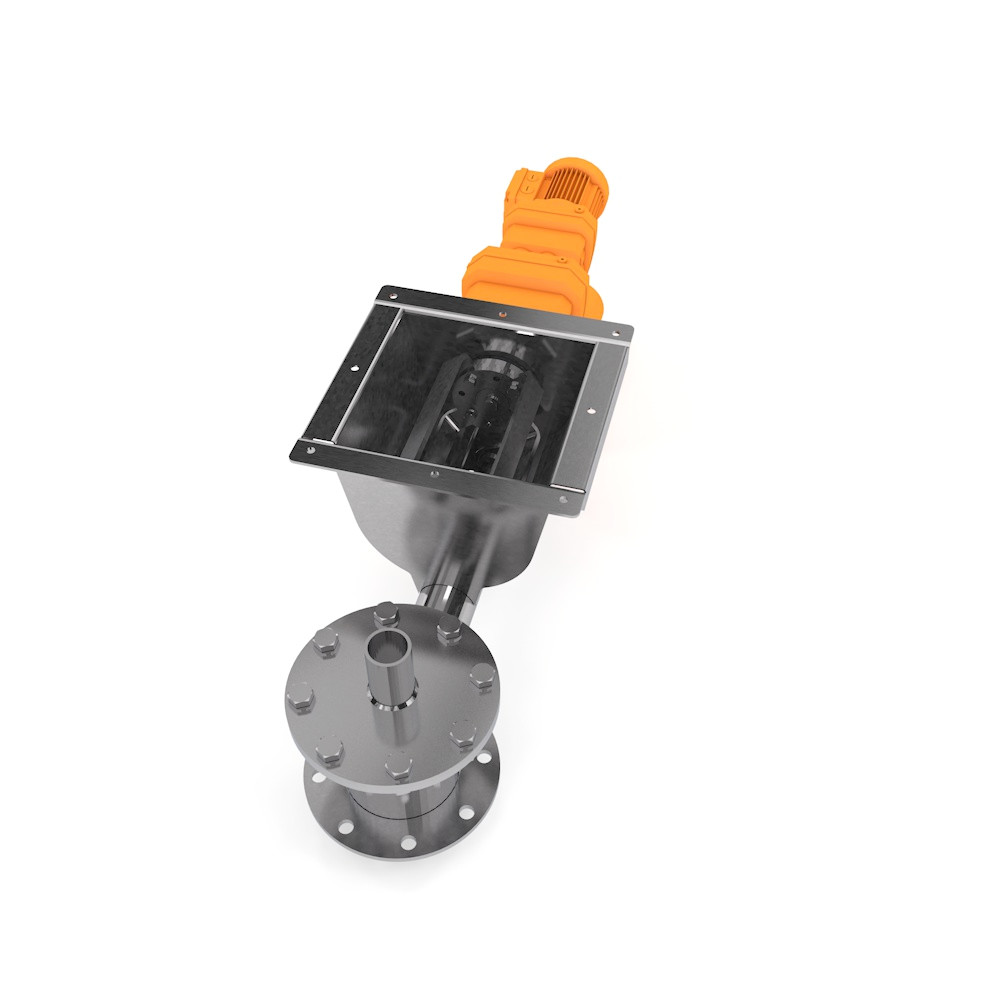

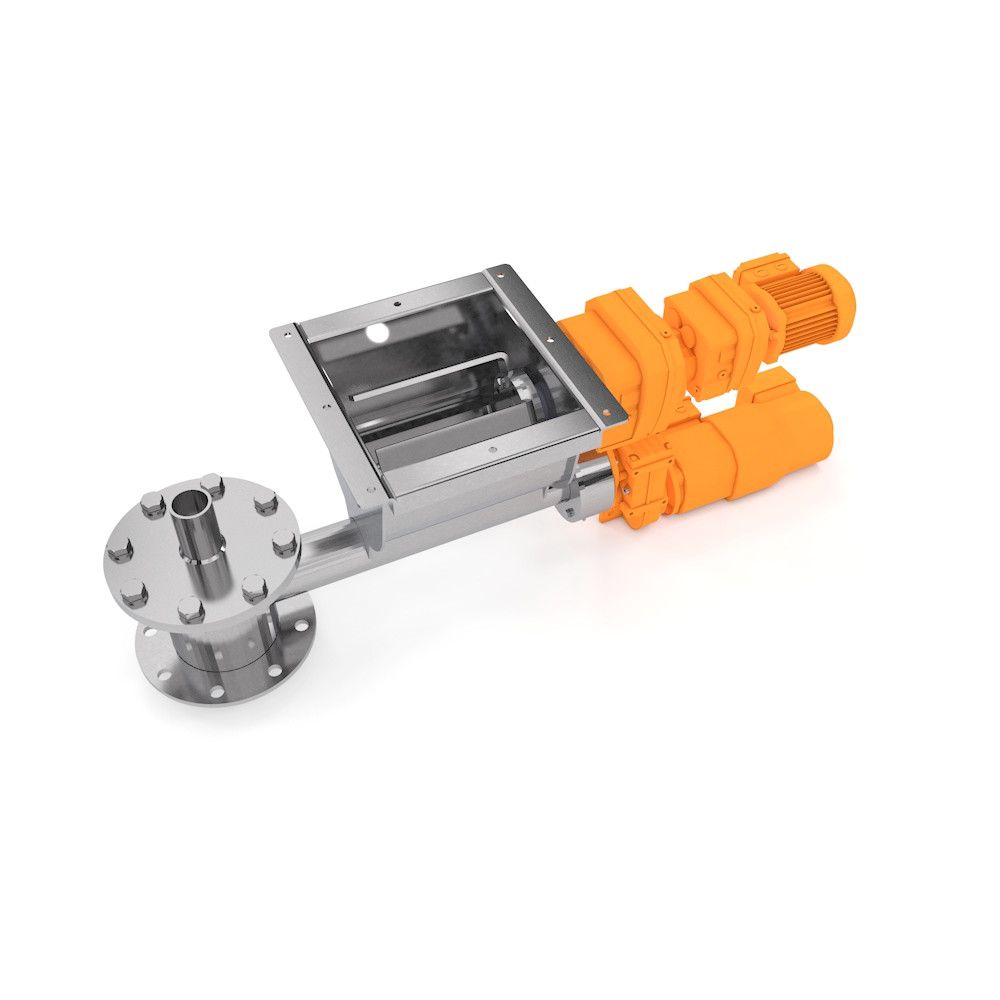

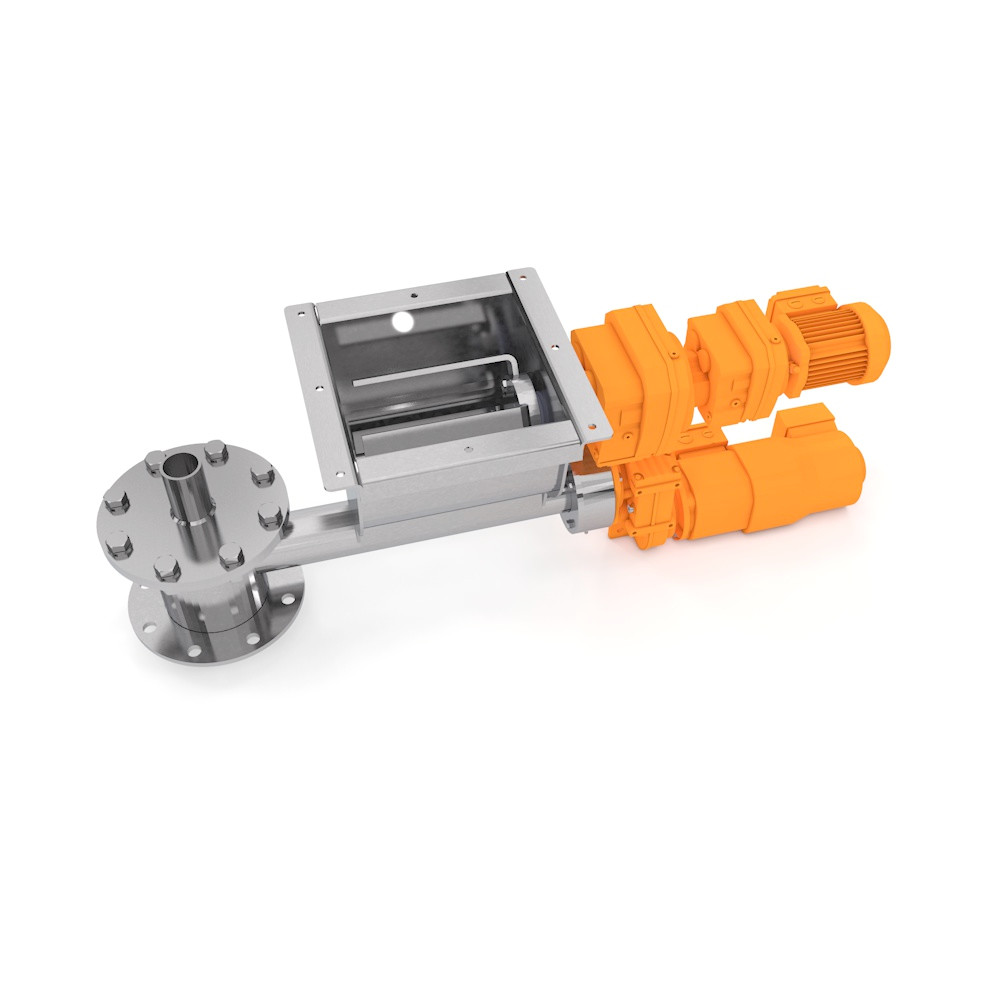

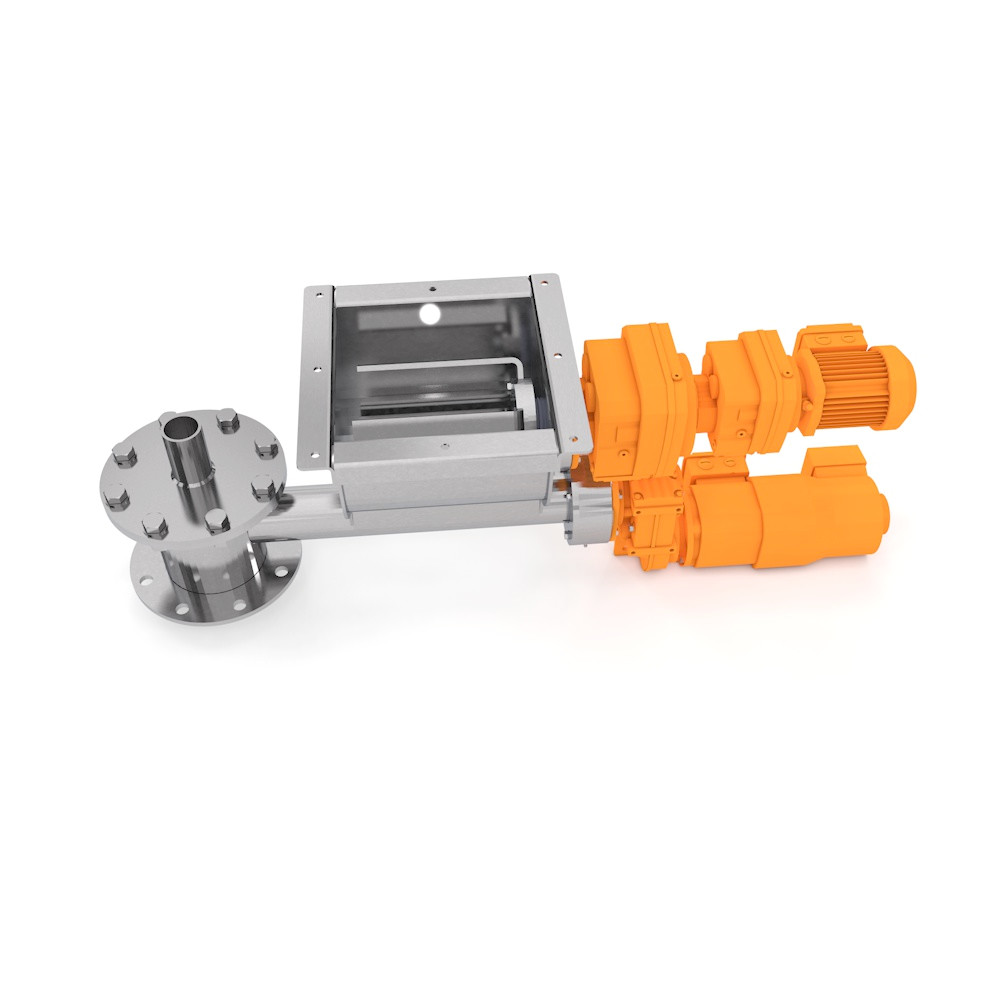

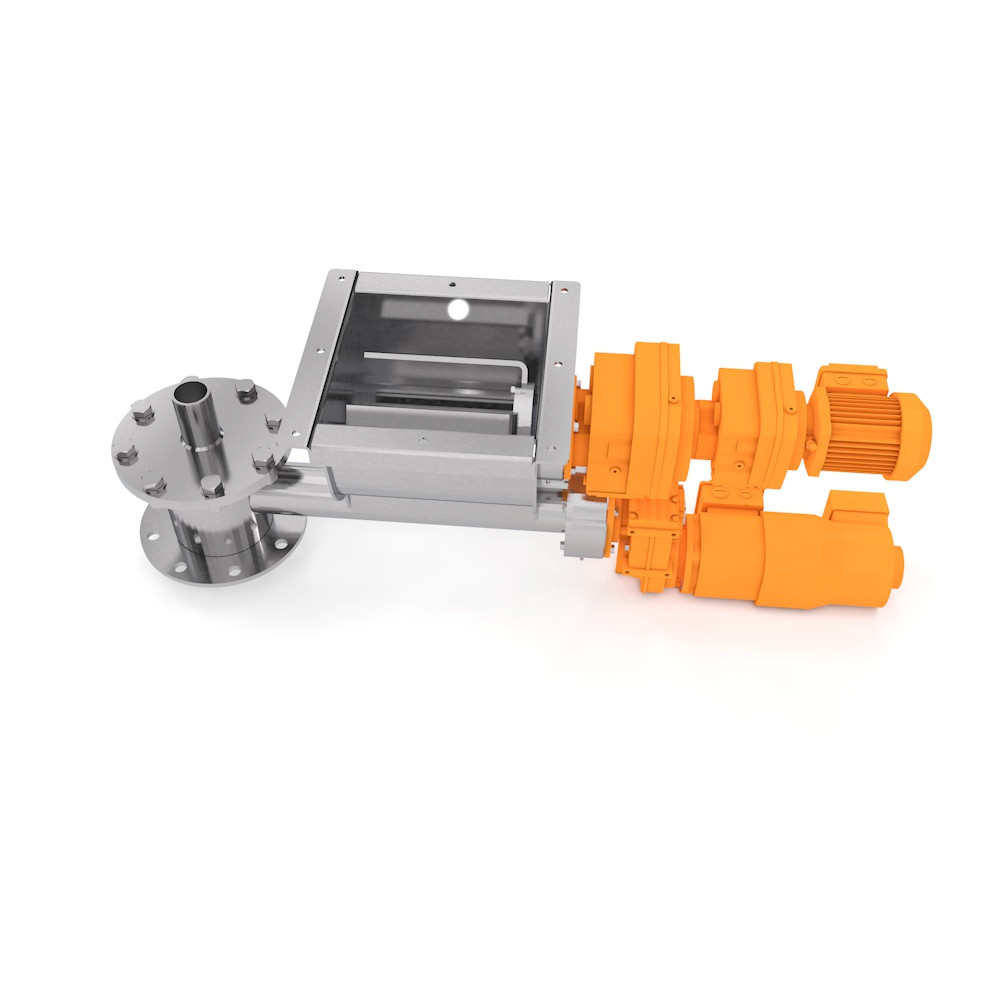

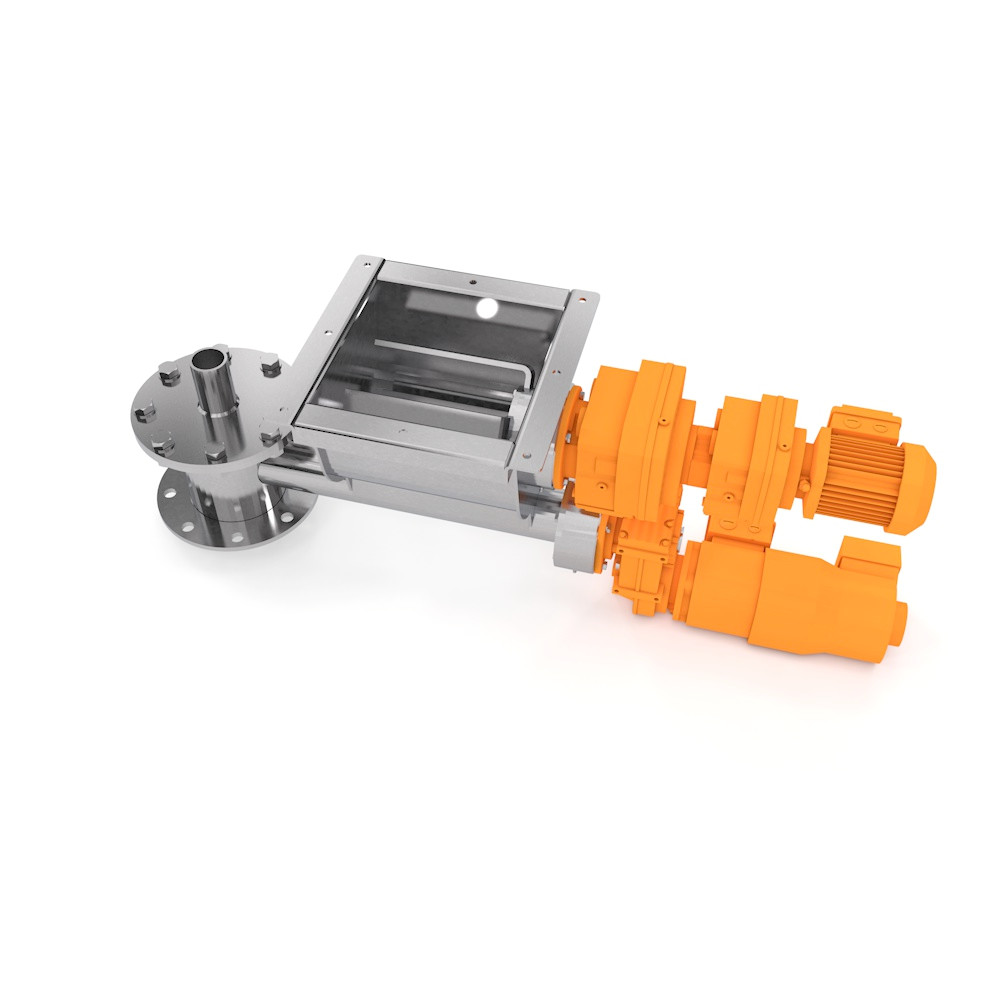

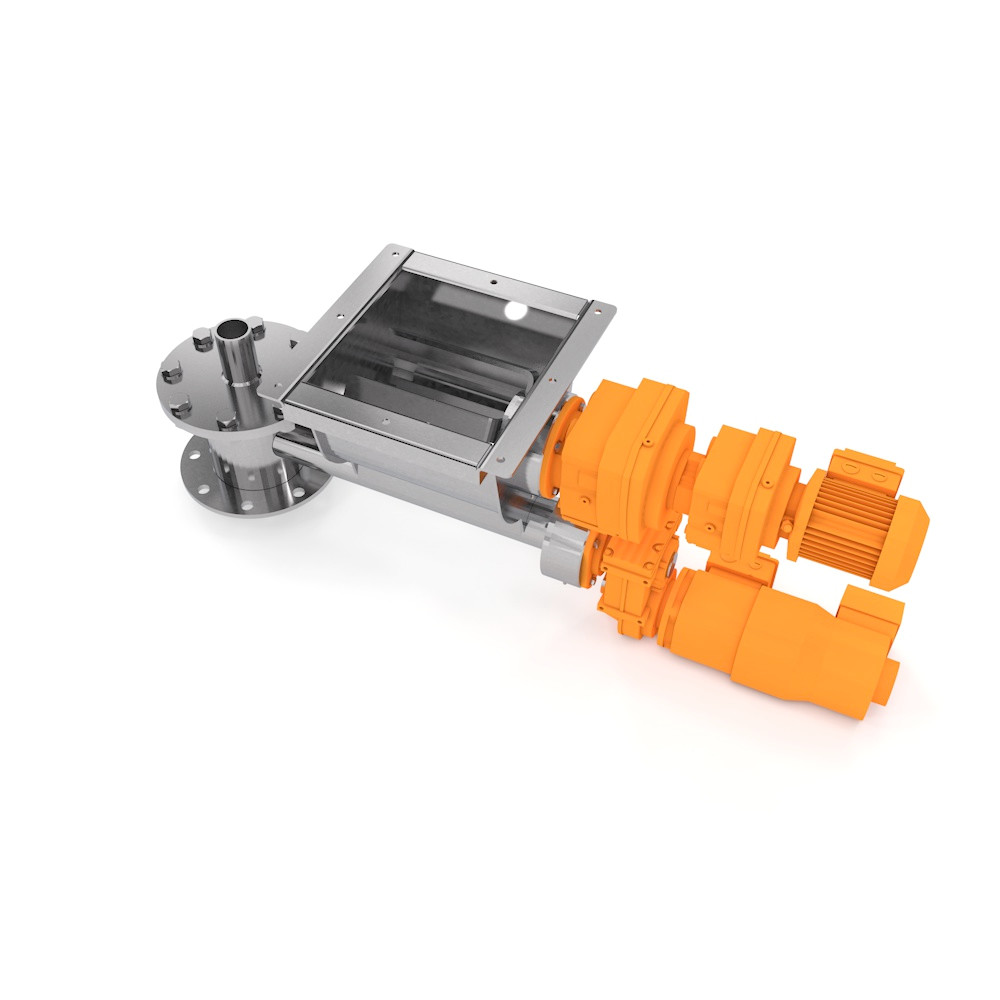

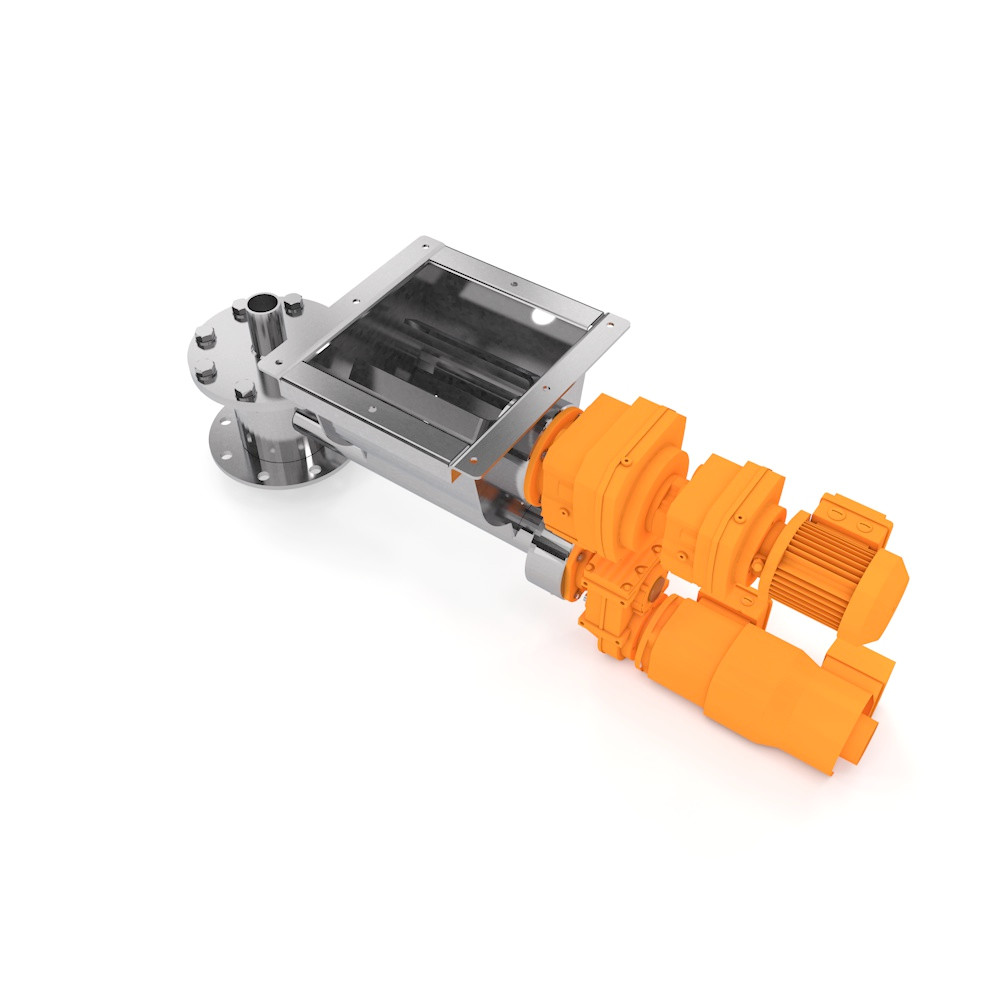

AGITATOR

Applications:

– Preferred for slightly cohesive bulk solids (e.g. flour)

– Preferably for hygroscopic bulk solids (e.g. urea)

Advantages:

– Small conveying capacities can be realized (fine dosing)

Technical Details:

– Inlet: 0,3 x 0,3 m

– Discharge capacity: 5 – 1.000 Kg

Other Configurations:

– Mostly in combination with weighing

– Suitable for inside dust explosion zone 20 and outside dust explosion zone 22

Materials:

– Normal steel S235 painted (< 480 µm)

– Stainless steel 1.4301

– Stainless steel 1.4571

BIN ACTIVATOR

Applications:

– Preferred for slightly cohesive bulk solids (e.g. flour)

Advantages:

– Cost-effective solution for discharging bulk material

Technical Details:

– Diameter 0.8 – 2.5 m

– Discharge capacity 5 – 150 m³/h

Other Configurations:

– Suitable for inside dust explosion zone 20 and outside dust explosion zone 22

Materials:

– Normal steel S235 painted (<480 µm)

– Stainless steel 1.4301

– Stainless steel 1.4571